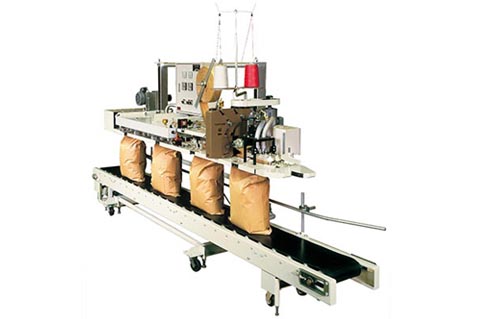

One-lined sealing and stitching ensure a perfect closure of paper bag.

Catalog Download

FEATURES

-

One-lined Closure of Paper Bag

Trimming, stitching, heat-sealing (inner PE), and heat seal tape sealing can be done all at one-lined and automatic process.

-

Simple Adjustment and High Performance

Easy to install and simple to maintain. Efficient and automatic to operate. Advanced technique embodied in its function.

-

Eight Standard Models For A Winder Application

Wider choice to suit bag specifications and products. Eight standard models plus optional items are available.

-

Easy Control of Heater Bar Temperature

Easy to adjust temperature and pressure of heater bar, so that no extra time required when to change bag thickness.

-

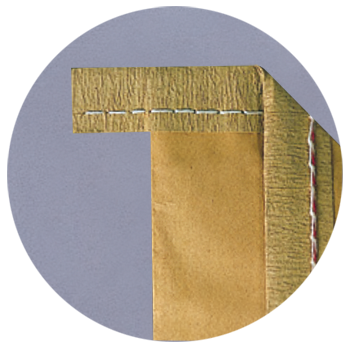

High Level of Sealed and Stitched Closure

Superior at a sift, dust, and insect proof. Products filled in bag can be completely protected.

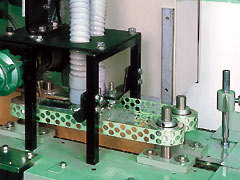

Carrier chain

Positively holds the upper part of bag all the way through the sealing process, to eliminate stitch failure nor lagging

Heat seal tape (Over Tape)

Automatically folded at the center, and applied over trimmed bag top. Automatic cut after over tape sealed.

Dust cleaner(option)

Vacuum opens the inner PE film liner in the bag mouth, and an air blast removes contamination in seal area for a positive seal.

Heater bar

Easy to control temperature and pressure to suit bag thick-ness.Upto six pairs of heater bars can be installed for efficient performance.

Sealer height adjustment

Sealer height can be changed by handle. Whole sealing unit can be moved vertically, so that the height is quickly and easily adjusted.

Code printer (NP-1), (option)

Code number or date can be printed by roller coder. A one-rotation clutch ensures accurate printing position. Print type is easily replaced.

■KS-16

For paper bag with and without inner PE film

■KS-324D

Inner bag seal and overtape seal after bag top folding without stitching.

Sift-proof closure of paper bag prevents product contamination.

■DS-7

Recommended for plain-stitch before heat seal tape sealing, e.g.

KS-12, KS-13, KS-14, etc.

| Revolution | 1,050 r.p.m.(normal) |

|---|---|

| Stitch width | 7.6mm. (fixed) |

| Speed | 7-8 m/min. |

STANDARD SPECIFICATIONS

| Speed | Heater | Drive Motors | Power Consumption |

Dimensions(mm) | Net Weight kg (approx) |

Stitching Head Machine |

Option | Applications | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Variable m/min. |

Capacity | Sealer | Stitcher | L | W | H | Dust cleaner |

Crepe tape |

|||||

| KS-S | 7~10 | ー | 0.4KW | 0.4KW | 1KW | 1,400 | 1,160 | 2,052 | 360 | DS-7C | × | standard | Crepe-tape only |

| KS-12 | 7~10 | 500W×4 | 0.4KW | 0.4KW | 3KW | 2,100 | 1,090 | 2,052 | 610 | DS-7A | × | × | heat seal tape, only |

| KS-12C | 7~10 | 500W×4 | 0.4KW | 0.4KW | 3KW | 2,450 | 1,190 | 2,052 | 660 | DS-7C | × | 〇 | |

| KS-13 | 7~10 | 500W×6 | 0.4KW | 0.4KW | 4KW | 2,200 | 1,090 | 2,052 | 640 | DS-7A | × | × | For 3-ply non gusseted bag, heat seal tape, and/or inner PE seal |

| KS-13C | 7~10 | 500W×6 | 0.4KW | 0.4KW | 4KW | 2,650 | 1,140 | 2,052 | 800 | DS-7C | × | 〇 | |

| KS-13D | 7~10 | 500W×6 | 0.4KW | 0.4KW | 4KW | 2,590 | 1,490 | 2,052 | 690 | DS-7A | 〇 | × | |

| KS-13DC | 7~10 | 500W×6 | 0.4KW | 0.4KW | 4KW | 3,070 | 1,490 | 2,052 | 850 | DS-7C | 〇 | 〇 | |

| KS-14 | 7~10 | 500W×8 | 0.4KW | 0.4KW | 5KW | 2,500 | 1,090 | 2,052 | 680 | DS-7A | × | × | For 4-ply non gusseted bag, heat seal tape, and/or inner PE seal |

| KS-14C | 7~10 | 500W×8 | 0.4KW | 0.4KW | 5KW | 2,900 | 1,090 | 2,052 | 850 | DS-7C | × | 〇 | |

| KS-14D | 7~10 | 500W×8 | 0.4KW | ー | 5KW | 2,850 | 1,490 | 2,052 | 730 | DS-7A | 〇 | × | |

| KS-14DC | 7~10 | 500W×8 | 0.4KW | ー | 5KW | 3,350 | 1,490 | 2,052 | 900 | DS-7C | 〇 | 〇 | |

| KS-16 | 7~10 | 500W×12 | 0.75KW | 0.4KW | 7.5KW | 3,000 | 1,090 | 2,052 | 760 | DS-7A | × | × | 6-ply non-gusseted bag or 3-ply gusseted bag heat seal tape and/or inner PE seal |

| KS-16C | 7~10 | 500W×12 | 0.75KW | 0.4KW | 7.5KW | 3,300 | 1,090 | 2,052 | 950 | DS-7C | × | 〇 | |

| KS-16D | 7~10 | 500W×12 | 0.75KW | 0.4KW | 7.5KW | 3,260 | 1,490 | 2,052 | 810 | DS-7A | 〇 | × | |

| KS-16DC | 7~10 | 500W×12 | 0.75KW | 0.4KW | 7.5KW | 3,720 | 1,490 | 2,052 | 1000 | DS-7C | 〇 | 〇 | |

| KS-23 | 7~10 | 500W×6 | 0.4KW | 0.4KW | 4KW | 2,420 | 1,430 | 2,052 | 670 | DS-7C | × | standard | For 3-ply nongusseted bag, inner PE seal |

| KS-23C | 7~10 | 500W×6 | 0.4KW | 0.4KW | 4KW | 2,850 | 1,790 | 2,052 | 720 | DS-7C | 〇 | standard | |

| KS-24 | 7~10 | 500W×8 | 0.4KW | 0.4KW | 5KW | 2,630 | 1,090 | 2,052 | 720 | DS-7C | × | standard | For 4-ply nongusseted bag, inner PE seal |

| KS-24D | 7~10 | 500W×8 | 0.4KW | 0.4KW | 5KW | 3,050 | 1,490 | 2,052 | 770 | DS-7C | 〇 | standard | |

| KS-26 | 7~10 | 500W×12 | 0.75KW | 0.4KW | 7.5KW | 3,040 | 1,090 | 2,052 | 820 | DS-7C | × | standard | For 6-ply nongusseted or 3-ply gusseted bag, inner PE seal |

| KS-26D | 7~10 | 500W×12 | 0.75KW | 0.4KW | 7.5KW | 3,460 | 1,490 | 2,052 | 870 | DS-7C | 〇 | standard | |

| KS-313 | 7~10 | 500W×6 | 0.4KW | 0.4KW | 4KW | 2,550 | 1,069 | 2,052 | 600 | ー | × | ー | ー |

| KS-324D | 7~10 | 500W×14 | 0.75KW | 0.4KW | 8KW | 3,900 | 1,460 | 2,052 | 850 | ー | 〇 | ー | |

●Sealing Temperature : 0~400℃

●Air Consumption : 200N /min.,5kg/cm in pressure

●Sealing Height : 800~1,730mm

●When dust cleaner installed, power consumption increases by 0.55 kw.

| Paper bag | Paper bag w/inner PE film | Paper bag w/inner PE film | Paper bag w/inner PE film (w/o stitching) |

|---|---|---|---|

|

|

|

|

|

|

|

|

Kraft paper bag

First stitched, then heat seal tape sealed for sift-proof closure.

Paper bag w/inner PE film

First seals inner PE and then stitches over seal line.

Paper bag w/inner PE film (w/o stitching)

<OPTION>

- dust cleaner (for inner PE film)

- outer lamination remover

- cutter (for cut tape)

- score cutter

- tape holder

- code printer

ALIGNMENT

KS-16

KS-324

Machine length depends on heater bar numbers , conveyor speed and option devices.