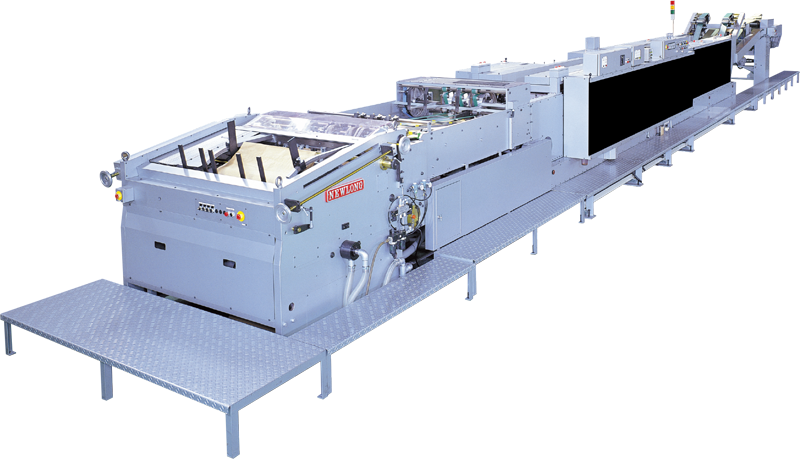

Model 713B bottomer is a high-performance machine designed to make both-end pasted bags with a valve from the tubes made by the tuber. It houses the main drive section in the gear box and requires less maintenance, is easy to operate and provides very high throughput. Also, the low-cost version Model 613B is available as a sister machine.

SPECIFICATIONS

| 613B | 713B | |

|---|---|---|

| Capacity*(bags/min.) | 120 | 250 |

| Bag Length (mm) | 365~830 | 365~830 |

| Tube Length (mm) | 490~1,020 | 510~1,020 |

| Tube Width(mm) | 280~550 | 280~550 |

| Bottom Width (mm) | 85~130 | 85~130 |

| Bottom Center Distance(mm) | 280~700 | 280~700 |

| Bottom Opening Width(mm) | 230~320 | 230~320 |

| Valve Sheet Length(mm) | 80~220 | 80~220 |

| Valve Sheet Width(mm) | 100~280 | 100~280 |

| Number of Ply | 2~4 | 2~4 |

| Main Drive Motor(kW) | 11 | 15 |

※Depending on various conditions.

712B MACHINE CONSTRUCTION

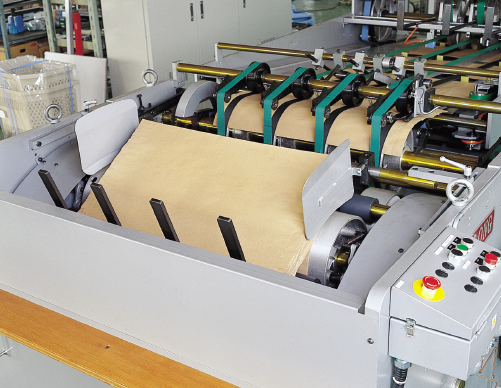

- ① ROTARY FEEDER

- ② TUBE ALIGNING UNIT

- ③ DIAGONAL CREASING UNIT

- ④ BOTTOM OPENING UNIT

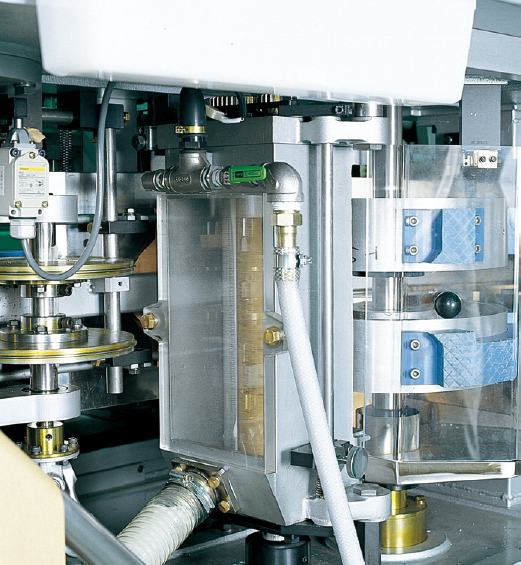

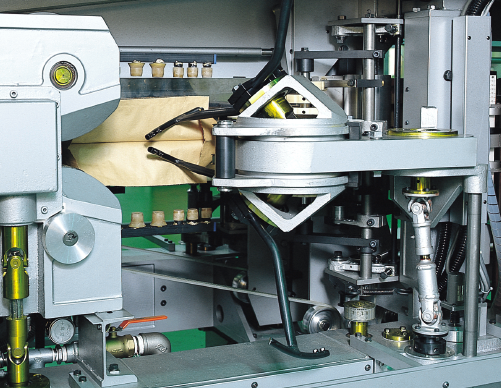

- ⑤ VALVE UNIT

- ⑥ BOTTOM PASTING UNIT

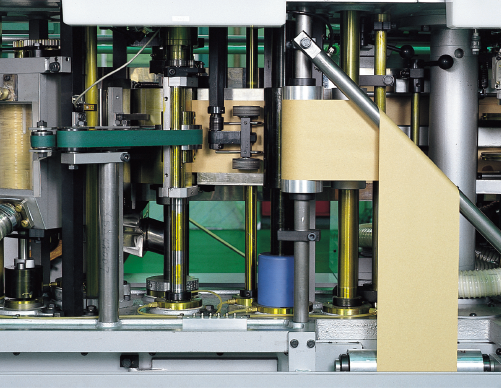

- ⑦ BOTTOM FORMING UNIT

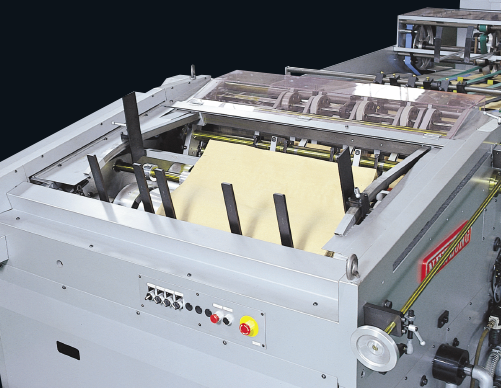

- ⑧ BOTTOM TURNING UNIT

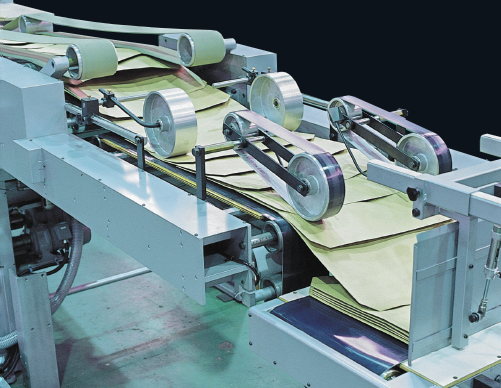

- ⑨ PRESSING AND COUNTING UNIT

- ⑩ STACKING UNIT

■713B

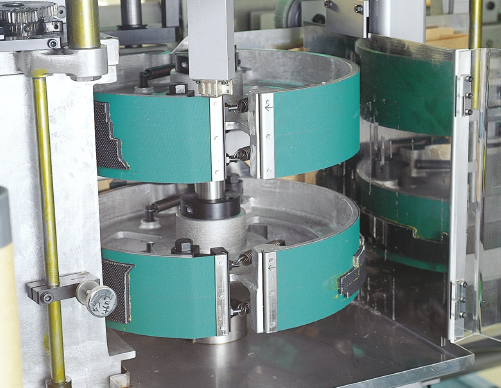

VALVE UNIT

BOTTOM OPENING UNIT

BOTTOM FORMING UNIT

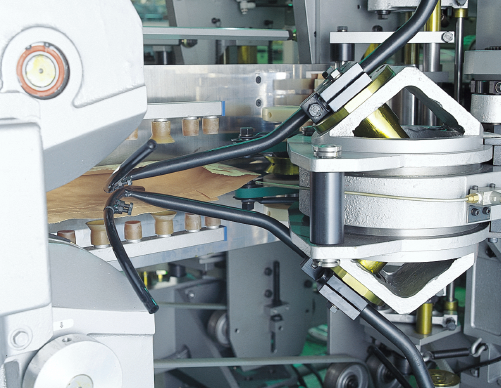

ROTARY FEEDER

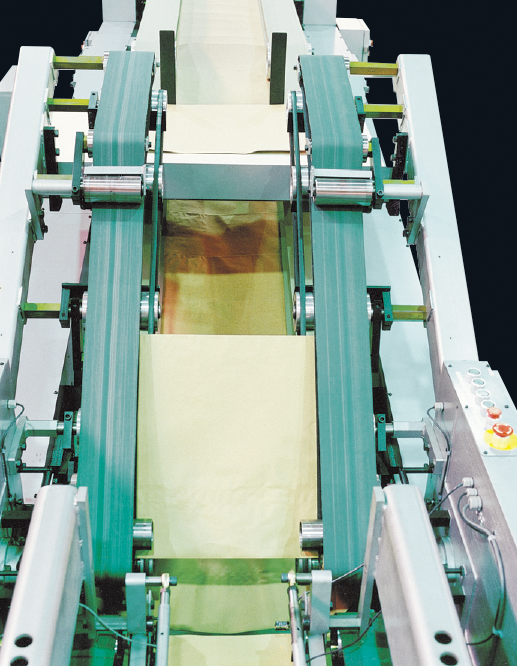

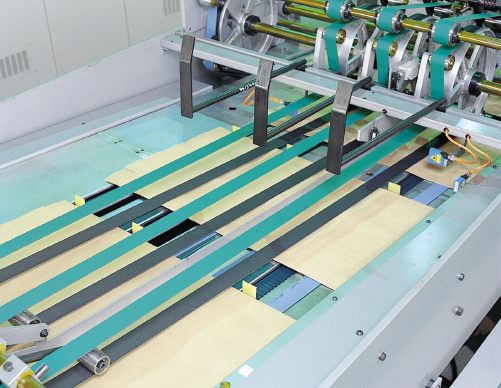

TUBE ALIGNING UNIT

■613B

ROTARY FEEDER

VALVE UNIT

TUBE ALIGNING UNIT

BOTTOM PASTING UNIT

BOTTOM OPENING UNIT

BOTTOM TURNING UNIT