■DS-2(II)

Single needle machine for closing of all kinds of filled bags made of multi-wall paper, PP/PE woven cloth, jute, cotton bags etc. Equipped with mechanically operated continuously running thread chain cutting knives. The operator has to guide the thread chain between these knives for cutting the thread chain at the end of the seam.

| Head Models | DS-2II |

|---|---|

| Revolution (rpm) | 1,400 |

| Stitch range (mm) | 7~12 |

| Oiling system | manual |

| Needle | DRX2 #25~26 |

| Thread | 20/6、20/9、30/12 |

| Cutter | mechanical |

■DS-C

Single needle machine exclusively designed for crepe-tape bound closing of filled bags made of multi-wall paper. Equipped with mechanically operated lever controlled cutting mechanism for automatic cutting of crepe-tape.

Note: Crepe-tape binder for tape width 55mm is included as standard. Special width crepe-tape binders available upon request.

| Head Models | DS-C |

|---|---|

| Revolution (rpm) | 1,400 |

| Stitch range (mm) | 7~12 |

| Oiling system | manual |

| Needle | DRX2 #25~26 |

| Thread | 20/6、20/9、30/12 |

| Cutter | mechanical |

■DS-6AC

Automatic single needle machine for both plain and crepe-tape bound closing of all kinds of filled bags. The machine will start and stop automatically by a micro-switch lever or photoelectric switch actuated by the bag being fed into the machine. In the same way, the machine stops after the bag passes through, and at the same time the thread/crepe-tape is cut automatically by built-in air cylinder operated guillotine type cutter.

| Head Models | DS-6AC |

|---|---|

| Revolution (rpm) | 1,400 |

| Stitch range (mm) | 7~10.5 |

| Oiling system | manual |

| Needle | DRX2 #25 |

| Thread | 20/6 |

| Cutter | pneumatic |

■DS-7C

Automatic swing needle machine specially designed to operate as an integrated part of sealing system such as with the NEWLONG KS Sealers. Features continuous motion feeding; the timed needle moves in epicyclical rotations as the bag passes through the sewing head. Power driven feed rollers ensure accurate feeding of the bag and avoid damage to the sack, which can sometimes be caused by a feed dog. Model DS-7C is equipped with pneumatic guillotine type crepe-tape cutter.

| Head Models | DS-7C |

|---|---|

| Revolution (rpm) | 1,600 |

| Stitch range (mm) | 8(fixed) |

| Oiling system | manual |

| Needle | DN-H29 #26 |

| Thread | 20/6、20/9 |

| Cutter | pneumatic |

■DS-7HS

The bag closing machine head is equipped with continuous (roll) feeder and swing needle for the feeding system. The high-speed operation is most suitable for over-tape closure in an automatic bagging line or over-tape (crepe tape) closure on model KS series heat sealers. Bags are held firmly by feeding chains between bag inserting position and thread-cutting (or over-tape cutting) position, until they are finally closed.

| Head Models | DS-7HS |

|---|---|

| Revolution (rpm) | 2,000 |

| Stitch range (mm) | 10(fixed) |

| Oiling system | Automatic oil bath system and external oil pump |

| Needle | DN-H29 #26 |

| Thread | 20/6、20/9 |

| Cutter | pneumatic |

■DS-9C

The fastest single needle bag closing machine (2700 rpm) for all kinds of filled bags. Well-balanced rotational parts ensure very little vibration. Ideally suited for use with height-speed bag filling lines where conveyor speed of 25m/min. Interchangeable with most existing sewing heads. All parts are protected against the effects of dust. A unique but simple enclosed oil bath lubrication system greatly extends the life of moving parts and reduces maintenance costs. Model DS-9C is equipped with pneumatic guillotine type crepe-tape cutter.

| Head Models | DS-9C |

|---|---|

| Revolution (rpm) | 2,700 |

| Stitch range (mm) | 7~10.5 |

| Oiling system | automatic |

| Needle | DR-H30 #26 |

| Thread | 20/6 |

| Cutter | pneumatic |

■ A2-B2L/A6-B2L [Model A series]

The series of model represent bag closing machines for various products e.g. foodstuff, fertilizer, feed, & chemicals, packed in paper, jute woven-cloth & polyethylene bags. Capable of handling 500 - 600 bags/hour capacity with automatic and simple operation. Right model suitable for working condition can be selected from a wide range of different models.

| Head Models | DS-2II | DS-C | DS-6AC | DS-6WAC | DS-9C |

|---|---|---|---|---|---|

| Revolution (rpm) | 1,400 | 1,400 | 1,400 | 2,000 | 2,700 |

| Stitch range (mm) | 7~11 | 7~11 | 7~10.5 | 7~10.5 | 7~10.5 |

| Oiling system | manual | manual | manual | manual | automatic |

| Needle | DRX2 #25~26 | DRX2 #25~26 | DRX2 #25 | DRX2 #25(×2) | DR-H30 #26 |

| Thread | 20/6,20/9,30/12 | 20/6,20/9,30/12 | 20/6 | 20/6 | 20/6 |

| Cutter | mechanical | mechanical | pneumatic | pneumatic | pneumatic |

| Start system | foot pedal | foot pedal | limit switch | limit switch | limit switch |

| Pedestal type | A2-P, A2-B, A6-P, A6-B | A6-P2L, A6-B2L, A6-BL2L | |||

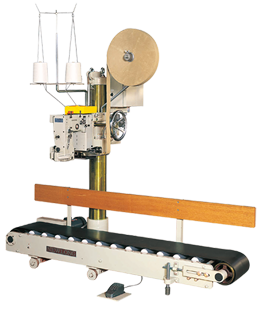

■A1-PB(DS-9C) + CM4900-3/ A1-PB(DS-9C) + CM4900-1/ A1-PB(DS-9C) + CP4900 [Model A1-PB Series ]

NEWLONG offers the latest in bag closing technology with the A1-PB height adjustable pillar; DS-9C high speed, oil enclosed sewing head. Available for both plain sewn and crepe-tape bound closure. This closing system can be used with a range of NEWLONG conveyors or an existing conveyor. Automatic infeed devices, Model CM4900-3, CM4900-1, and CP4900 can be mounted on Model A1-PB(DS-9C) pedestal type bag closing machine.

| Head Models | A1-PB(DS-9C) |

|---|---|

| Revolution (rpm) | Max.2,700r.p.m |

| Stitch range (mm) | 7~10.5 |

| Oiling system | automatic oil bath system |

| Thread | 20/6、20/9 |

| Cutter | pneumatic |

| machine weight | 320 |

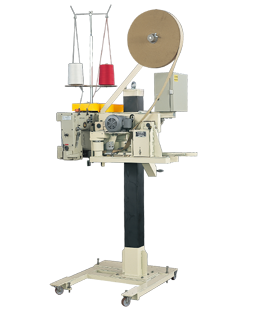

■B2 (DS-2Ⅱ)

The sewing head can be moved up and down simply by operating a handle and the machine can be operated easily. Provision of casters allow the machine to be moved easily. Bags made of various types of material can be stitched.

| Head Models | DS-2Ⅱ |

|---|---|

| Capacity (bags/hour) | 200 to 300 |

| Dimensions (mm) | L1,180×W830×H2,200 (including thread stand) |

| Power required | 200W, Clutch motor, 4P (single phase or three phase motor) |

| Size ot carrier table (mm) | L445×W328 |

| Sewing height (mm) | 290 to 750 (Table surface to needle center) |

| Net weight (kg) | 149 |

■B2 (DS-C)

The sewing head can be moved up and down simply by operating a handle and the machine can be operated easily. Provision of casters allow the machine to be moved easily. The crepe tape unit can be installed for automatic setting of tape and provides beautiful finish.

| Head Models | DS-C |

|---|---|

| Capacity (bags/hour) | 200 to 300 |

| Dimensions (mm) | L1,180×W830×H2,200 (including thread stand) |

| Power required | 200W, Clutch motor, 4P (single phase or three phase motor) |

| Size ot carrier table (mm) | L445×W328 |

| Sewing height (mm) | 290 to 750 (Table surface to needle center) |

| Net weight (kg) | 149 |

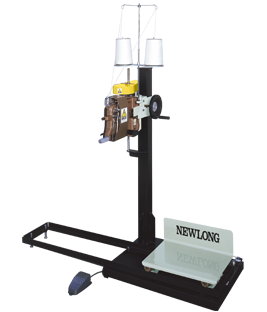

■F5 (DS-5Ⅱ)

The sewing head can be moved up and down simply by operating a handle and the machine can be operated easily. Provision of casters allow the machine to be moved easily. The low position of the carrier table allows easy loading and un-loading of bags.

| Head Models | DS-5Ⅱ |

|---|---|

| Capacity (bags/hour) | 150 to 250 |

| Dimensions (mm) | L1,400×W490×H1,400 (including thread stand) |

| Power required | 200W (single phase motor) |

| Size ot carrier table (mm) | L450×W305 |

| Sewing height (mm) | 450 to 860 |

| Net weight (kg) | 60 |

■CM4900-1

Automatic infeed device for plain sewn closure on paper bags and PP/PE woven cloth bags. It can be mounted on Model A1-PB(DS-9C) pedestal type bag closing machine.

| Head Models | DS-9C |

|---|---|

| Sewing Head Height | 720-1,220 mm from floor to needle |

| Brake Motor for head | 4P, 3 Phase, 0.75 kW or 0.4 kW depends on conveyor speed |

| Start/Stop | Photo-switch |

| Max. Speed | 2,700 r.p.m. |

■NP-7 Portable bag closer

Single thread chain stitch with one each needle and looper

Single thread chain stitch with one each needle and looper. Oil pump lubrication system. Oil lines direct lubricant to maim moving elements.

| Speed(r.p.m.) | 1,700+200 |

|---|---|

| Stitch range (mm) | 8.5 (3 per inch) fixed |

| Needle | DN×1 - #25 |

| Drive motor | 65W 50/60Hz, 1-ph. 12V, 24V, 110V, 220V or 240V (please specify one when ordering.) |

| Weight (kg) | 5.65 (13 lbs) with thread |

* TAPE BINDING ATTACHMENT available at extra cost.

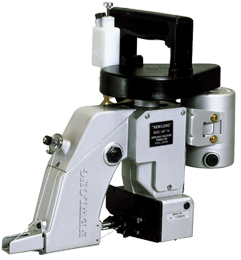

■PORTABLE BAG CLOSER NP-3II

DOUBLE THREAD CHAIN STITCH with one each needle and looper

Double thread chain stitch with one each needle and looper.

Double thread chain stitch, makes tight closures.

| Speed(r.p.m.) | 1,350±150 |

|---|---|

| Stitch range (mm) | 8.5(3 per inch) fixed |

| Needle | DN×1 #25 |

| Drive motor | 60/65W 50/60Hz, 1ph. 12V. 24V,110V,220V or 240V. (please specify one when ordering.) |

| machine weight | 6.27(14 lbs) with thread |