PRODUCTS

A Series

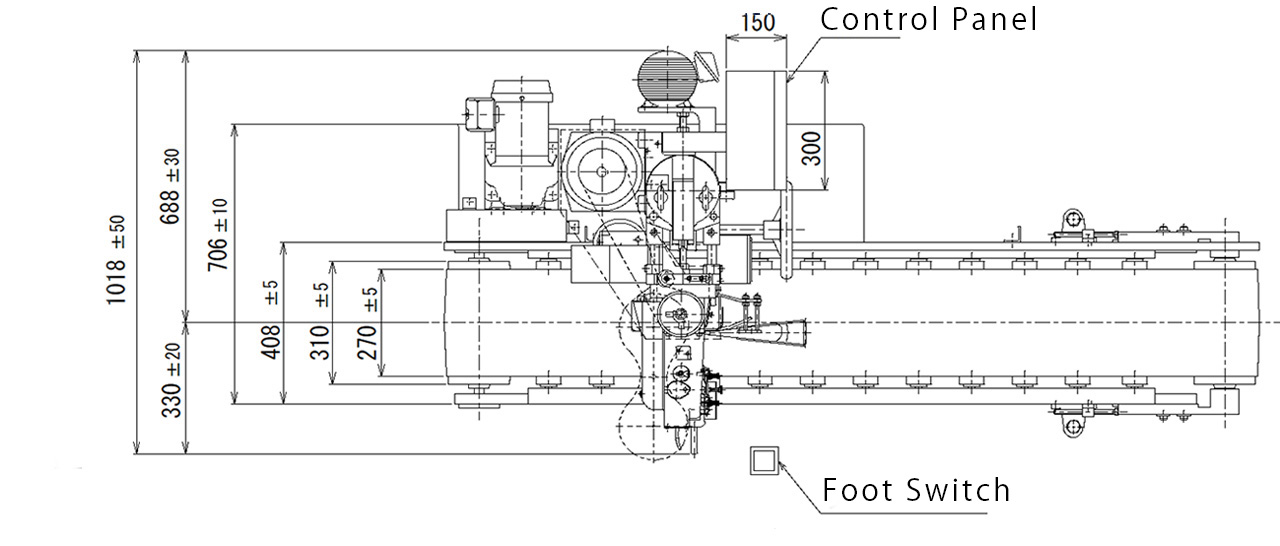

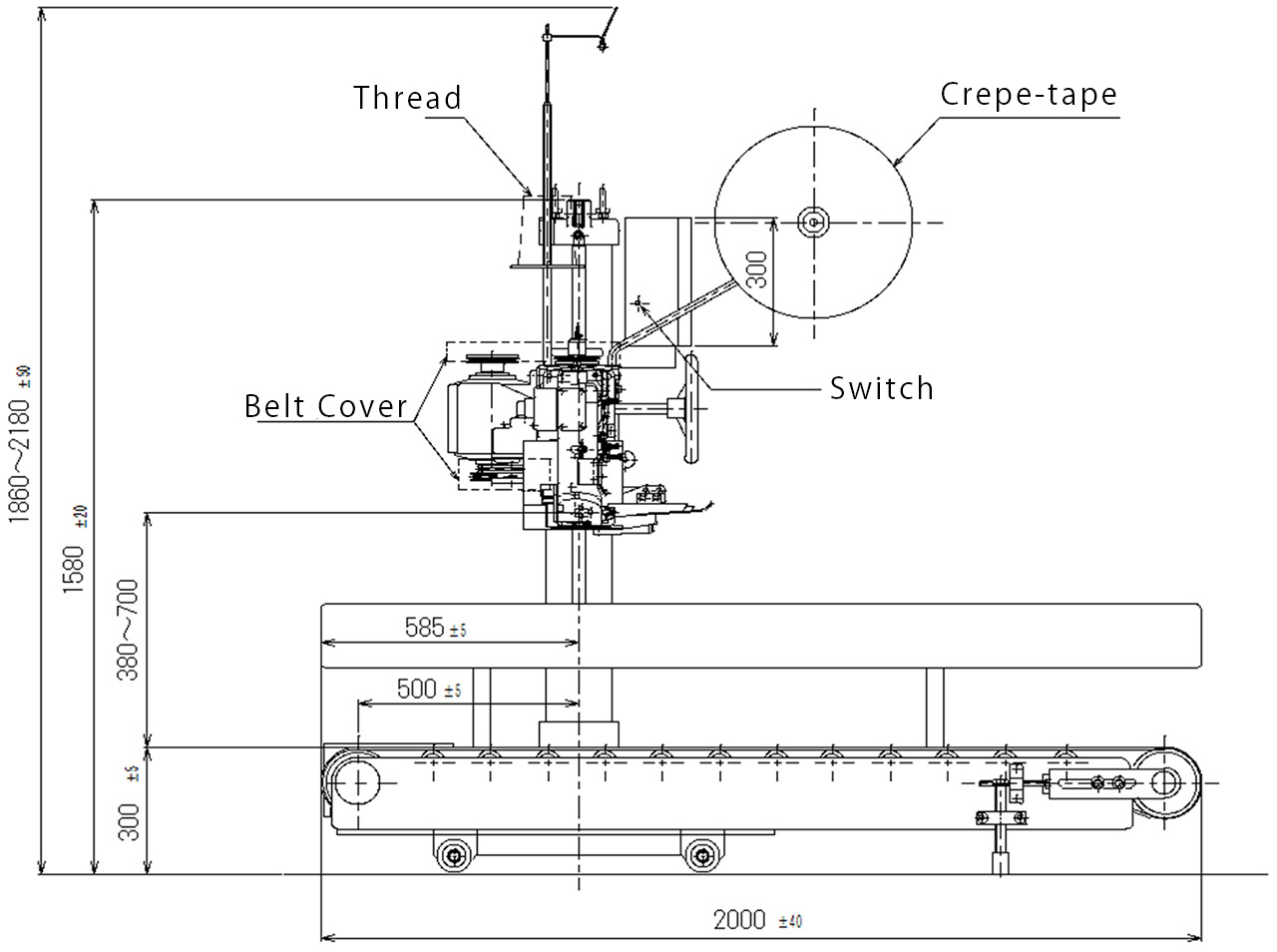

A2-B2L : Automatic sewing machine with conveyor

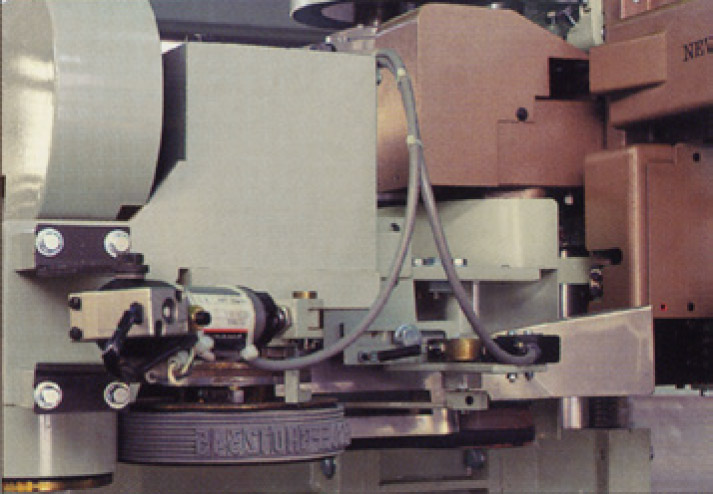

Sewing Head : DS-6AC (Manual Bag Feeding), DS-9C (Manual Bag Feeding)

With a processing capacity of 500–600 bags per hour and automated operation, Model A2-B2L offers easy operation. A broad lineup of models are available to meet different packaging conditions and requirements.

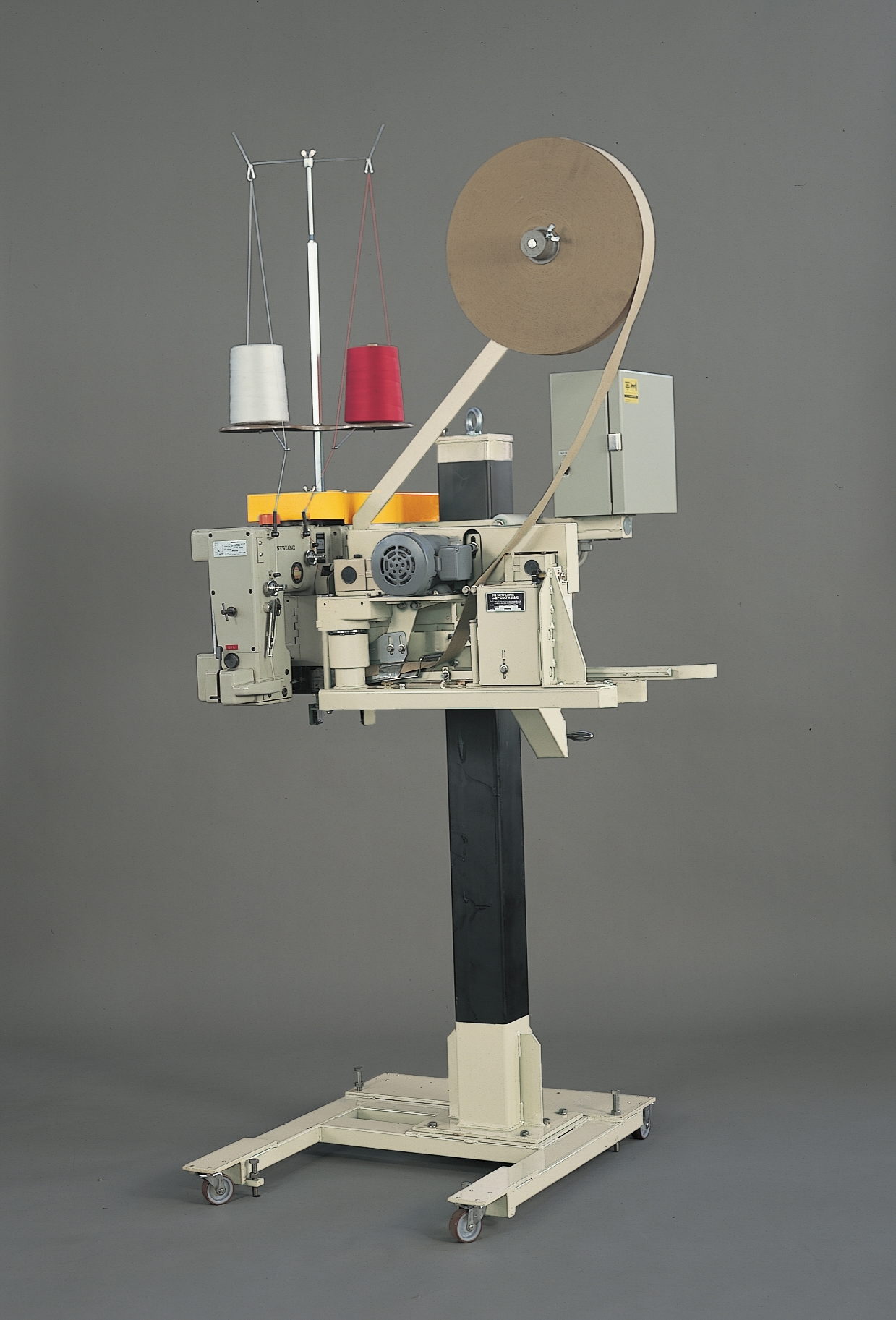

A2-B : Sewing machine with conveyor

Sewing Head: DS-2-2, DS-C

A clutch motor is used to drive the sewing machine head.

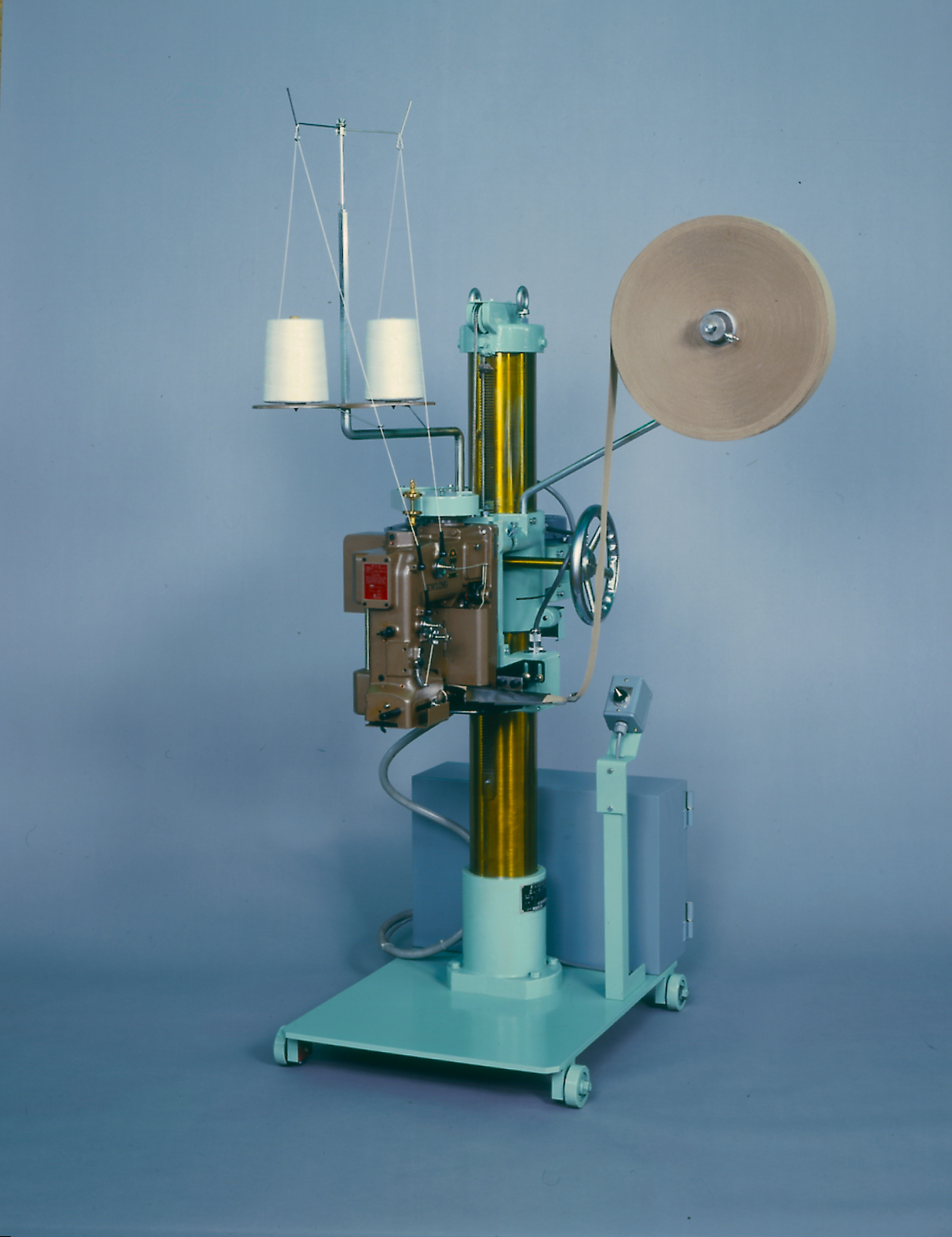

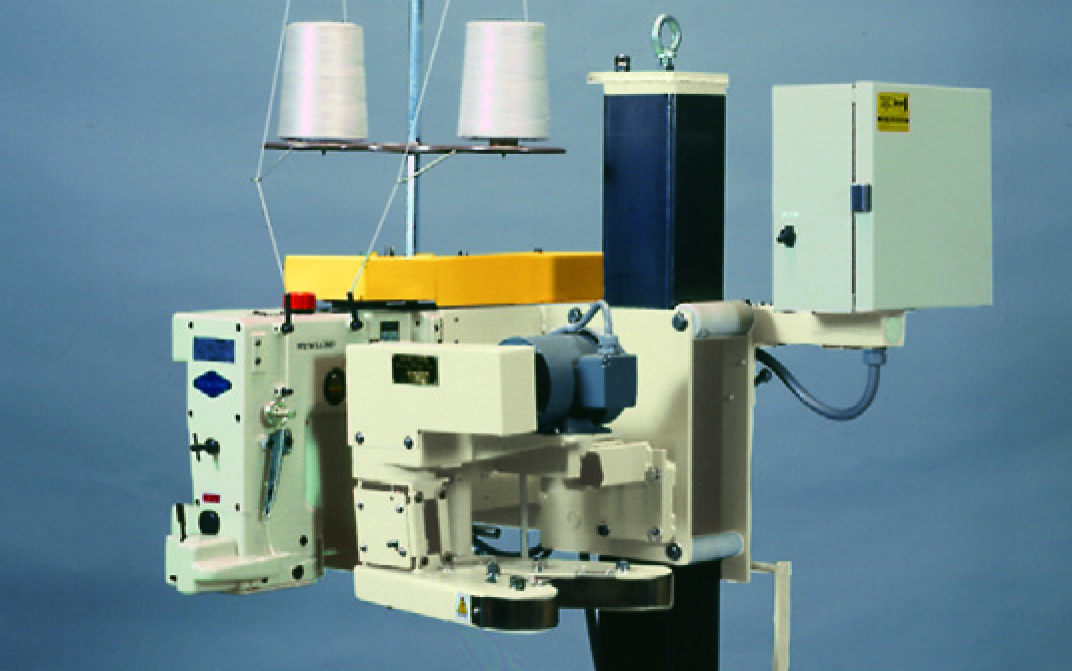

A1-PB : Automatic sewing machine without Conveyor

Sewing Head: DS-9C

A conveyor-less model that can be integrated with existing production lines or automatic bagging machines. Automatic infeed devices are installable.

Automatic sewing machine without Conveyor

Sewing Head:DS-9C、DS-6AC

Conveyor-less type of Model A2-B2L that can be intergraded with existing production lines or automatic bagging machines.

Option 1: Printer

By integrating the DP-6, numbering and other systems; date, lot number, etc. can be printed.

Option 2: Automatic Infeed Devices CM49000-1

Automatic infeed device for plain sewn closure on paper bags and PP/PE woven cloth bags to A1-PB. CM4900-1 is for feeding only.

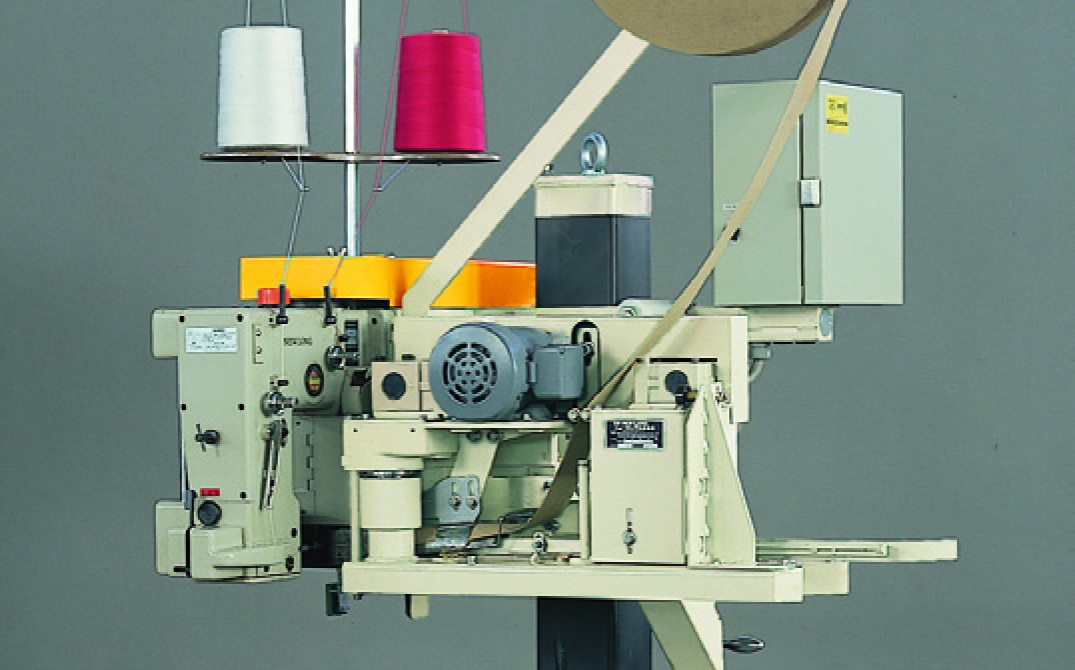

Option 3: Automatic Infeed and trimming devices CM49000-3

Automatic infeed and Bag top trimming device for crepe tape bound closure on paper bags. Crepe-Tape Width : Standard 55 mm, other width available.

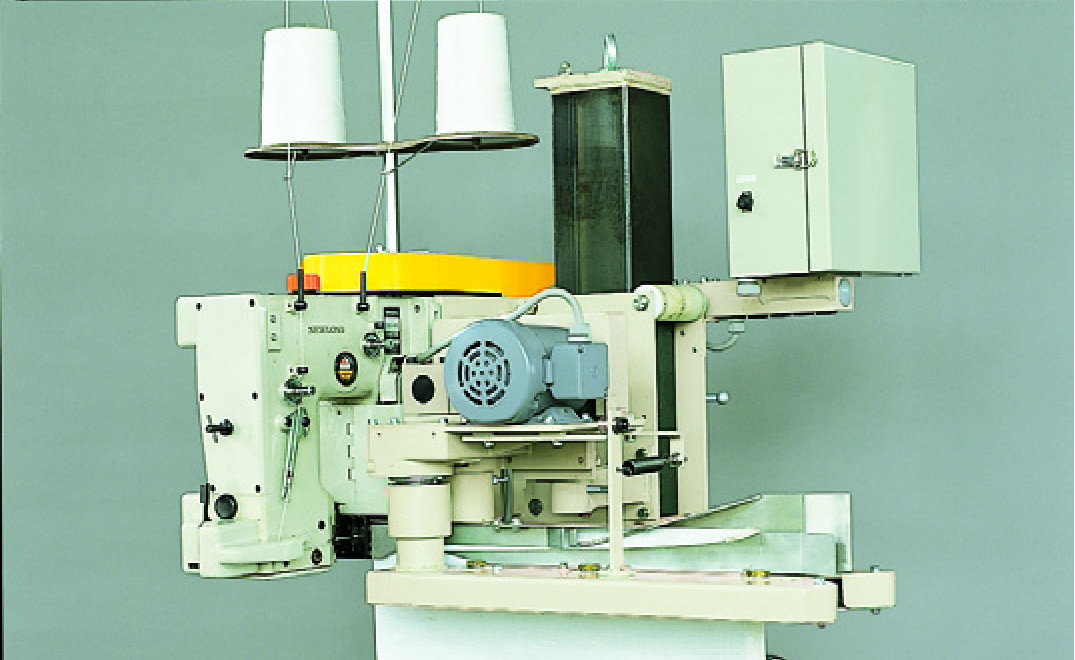

Option 4: Automatic Infeed and Folding Devices CP49000

Automatic infeed and Bag top folding device for plain sewn closure on PP/PE woven cloth bags. Bag top empty space required for folding : 170 – 200 mm Bag top folding depth : 30 – 60 mm.