PRODUCTS

Fan-top Tying Machine

FT-40 (Air Type)

Operates solely with air, no electrical power required. Twist-ties with metal cores are used for bundling (Optional resin ties are also available) . The top of the bag is fan-folded and secured with a twist tie.

| Machine Dimensions | 550×520×550mm |

| Weight | 68kg |

| Air Consumption | 6.5NL/Cycle 0.5MPa |

| Capacity | 1.5 seconds per cycle |

FT-50-AC (Electrical Type)

The electric design ensures quiet operation and high durability. Requires only a standard 100V outlet, making it easy to be installed anywhere. Features a safety-equipped open/close cover. The machine automatically stops when the cover is opened.

| Machine Dimensions | 535×560×420mm |

| Weight | 54.5㎏ |

| Power Required | 100V 850W |

| Capacity | 1.2 seconds per cycle |

| Option 1 | Includes a stand that allows the main unit to be tilted and secured. |

| Option 2 | A sensor detects bags and automatically starts tying fan-tops. |

| Option 3 | The tying width can be changed from the standard 4 mm to 8 mm or to an eco-friendly tie option. |

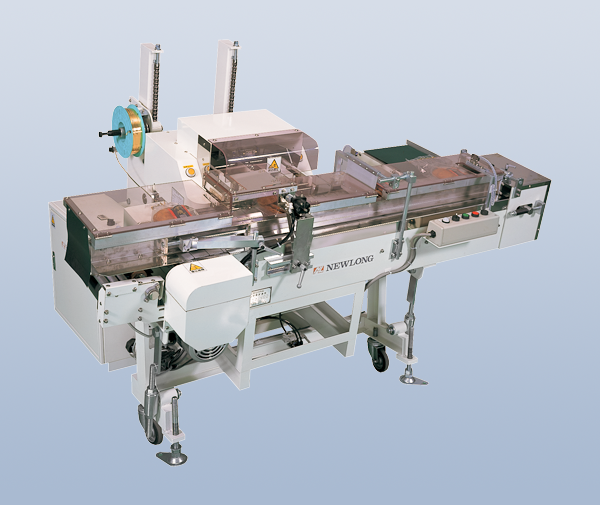

FT-ATH (Automatic Fan-Top Tying Machine Horizontal Type)

This machine receives pre-packaged products from the previous process from the bag bottom, detects it with a sensor, and transfers it by a conveyor that moves one pitch at a time. As the product reaches the fan-fold tying unit via the conveyor, it is automatically centered at the bundling section when the conveyor stops. The bag is then fan-folded and tied, and is discharged at the next intermittent conveyor movement.

| Machine Dimensions | Electrical Type (with FT-50AC) 1890x1520x1735mm |

| Machine Dimensions | Air Type (with FT-40) 1890x1520x1735mm |

| Weight | 470kg |

| Power Required | Electrical Type (with FT-50AC) 200V 3PH 2.8kW |

| Power Required | Air Type (with FT-40) 200V 3PH 1kW |

| Capacity | Electrical Type (with FT-50AC) 40Bags / Minute |

| Capacity | Air Type (with FT-40) 30 Bags / Minute |

| *Depends on product character, bag size, and other potential factors |

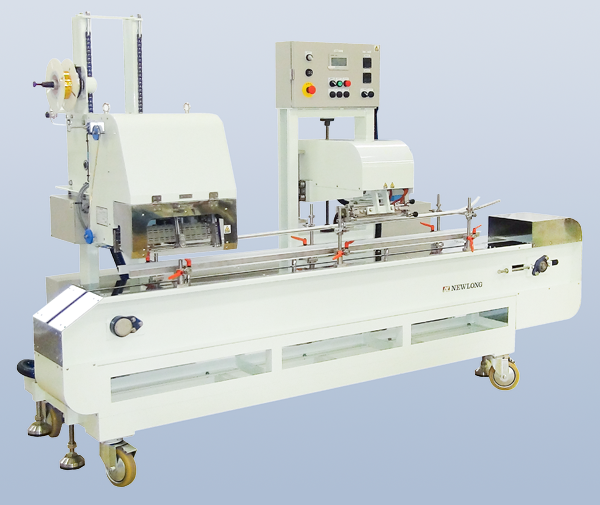

FT-ATV (Automatic Fan-Top Tying Machine Vertical Type)

This machine receives packaged products, and stands it up via a chute. A sensor detects the bag, which is then held between sponge pads and advanced one pitch at a time using a cylinder. At the second station, the bag’s position is corrected. At the third station, the bag is fan-folded and tied before being discharged at the next process. The sponge pads at all three stations are operated simultaneously by a single cylinder. This machine inserts the bag into the sealing unit, then transfers the sealed bag to the tying section using an air cylinder, where the bag end is fan-folded and tied.

| Power Required | 100V 1PH 100W 200V 3PH 2kw |

| Capacity | 35 Bags / Minute |

| *Depends on product character, bag size, and other potential factors |