PRODUCTS

Slitter

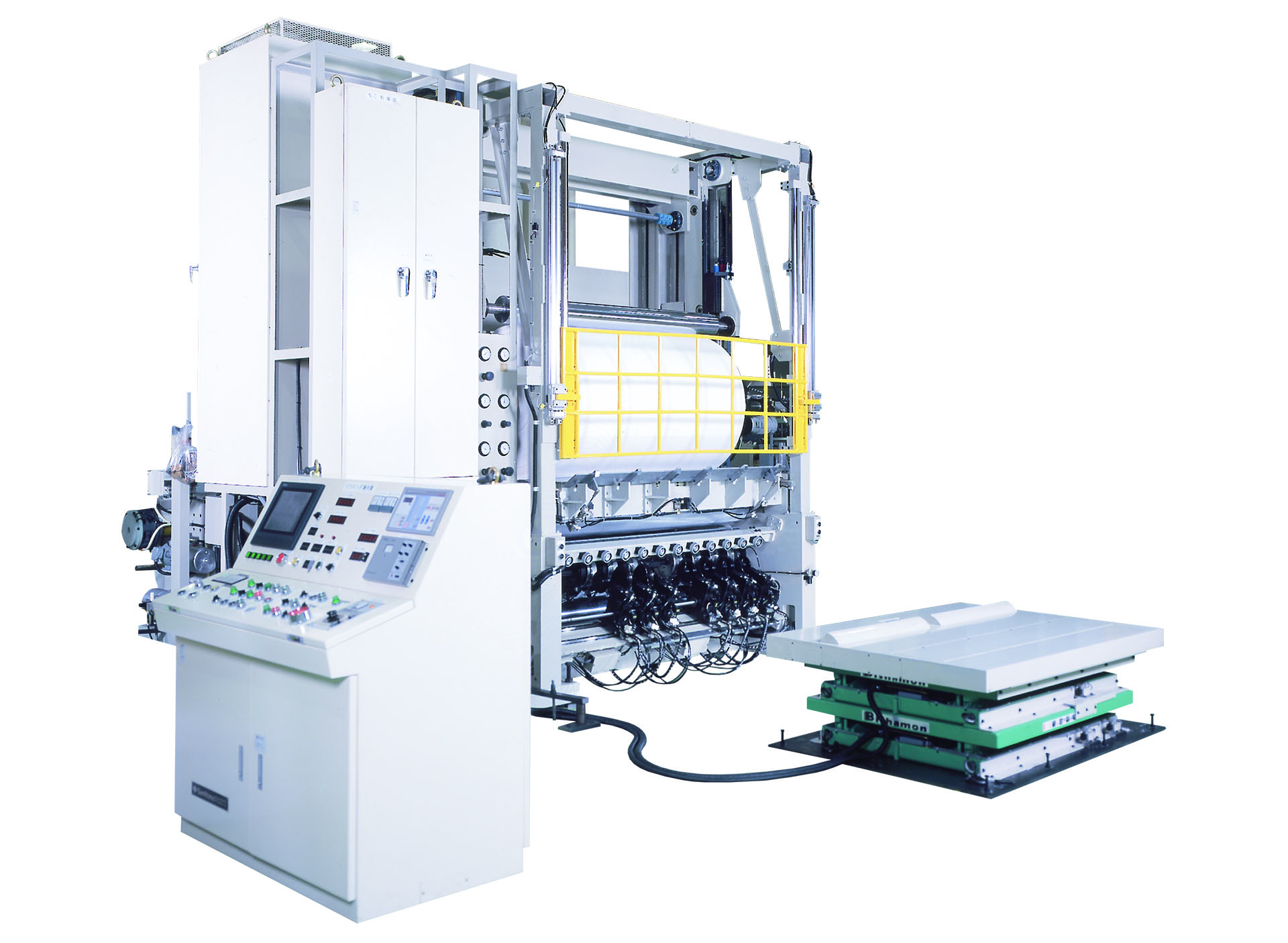

SW Series

High-speed surface rewinding slitter for large-diameter rolls

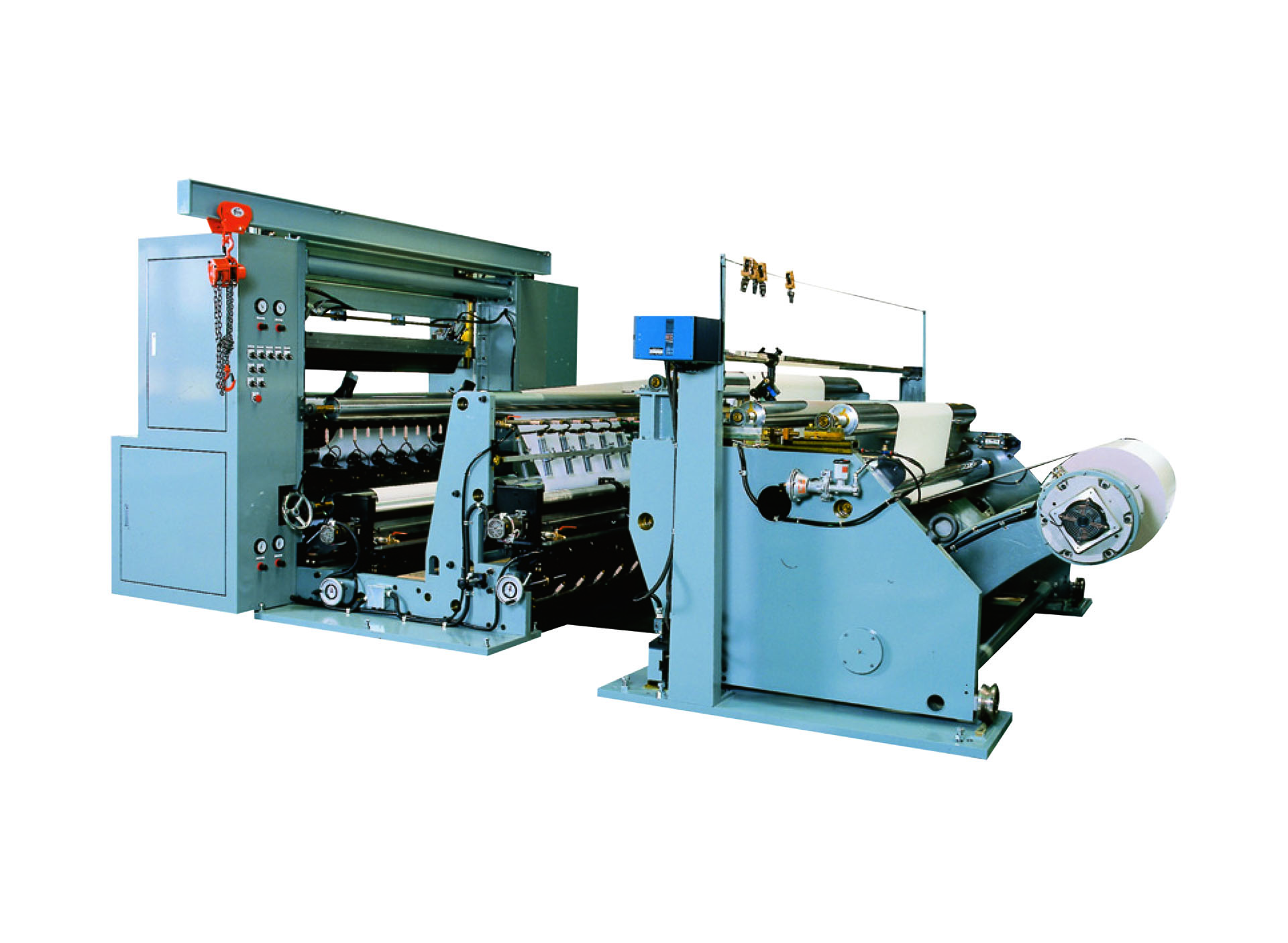

S Series

Surface rewinding slitter for small rolls

- Ideal for high-speed, large-volume slitting of paper for commercial printing (sheet-fed and roll-fed).

- Work efficiency is improved by equipping the optional NC-controlled slitter unit.

- Achieves ultra-high-speed operation of 1500 m/min through excellent roller balance, robust frame design, and an innovative twin motor drive control system.

- Stable tension is maintained even at high speeds with the use of a water-cooled disc brake system.

- Widely used as a slitter for small rolls intended for general consumers, such as fax paper and cash register paper.

- Available in a series covering widths from 500 mm up to 2000 mm.

- Equipped with three feed rolls, significantly reducing acceleration and deceleration times.

- Compatible with various optional units, including an inline flexographic printing unit.

- The control panel is integrated into the main body, achieving both ease of operation and space efficiency.

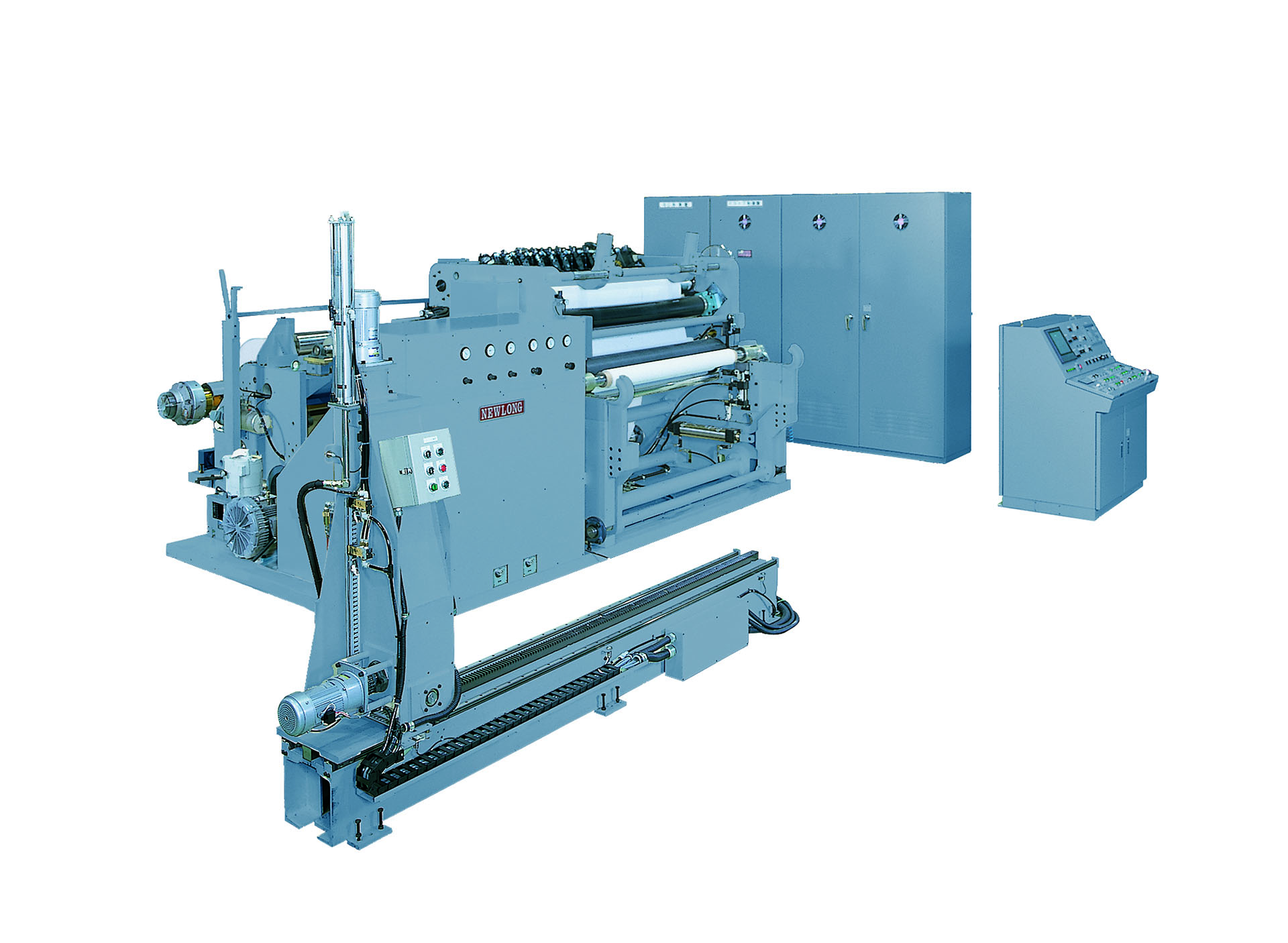

K Series

K-Standard, Single-Shaft Center Drive Slitter

K Series

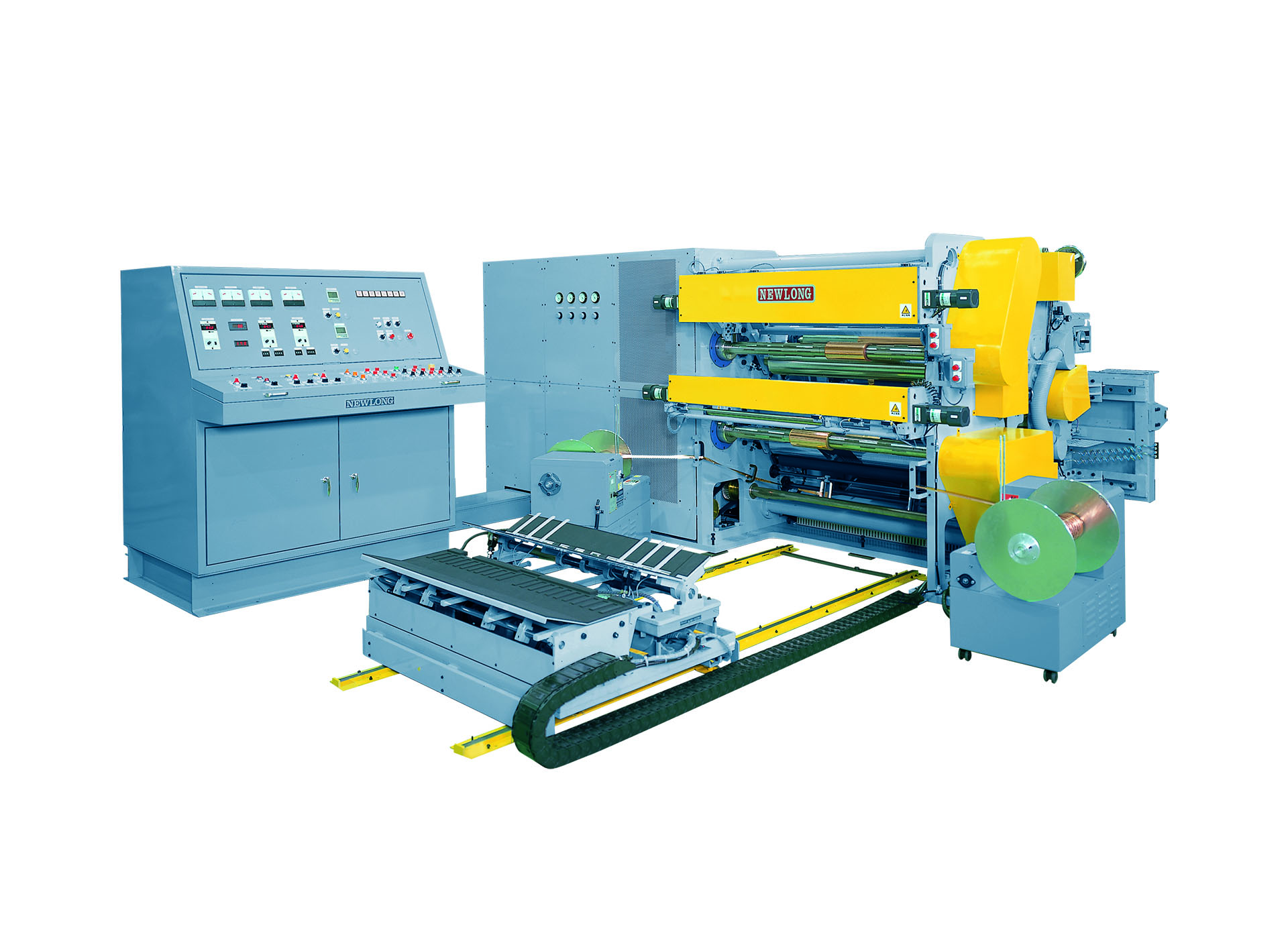

KD, Two-Shaft Center Drive Slitter

- Incorporates a three-feed-roll system (with a central suction roll) to enhance the independence of unwind and rewind tension control.

- Equipped with a shaft deflection correction mechanism to improve winding quality for wide and large-diameter rolls on 3-inch paper cores.

- Hydraulic touch pressure control enables hard and high-quality winding, with options for taper pressure and contactless (floating) winding.

- Standard product lifting arms simplify the loading/unloading of finished rolls and installation of air shafts.

- Optional shaftless unwind unit simplifies roll loading and unloading of rolls.

- Utilizes an S-wrap feed roll system (with one suction roll) to enhance the independence of unwind and rewind tension control.

- When equipped with air shafts, dual independent tension control enables high-quality winding.

- Friction shafts allow for high-quality winding even with substrates of varying thickness or uneven stretch.

- Optional shaftless unwind unit simplifies the loading and unloading of rolls.

K Series

KDC, Two-Shaft Center Drum Slitter

- The center-drum dual-shaft winding system (combined surface and center drive) enables gentle winding of narrow-width, multi-strip products.

- Open-loop tension control helps reduce overall system cost.

- Simplified paper path design allows for a compact and cost-effective dual-shaft winding system.

Standard Specifications

| SW Series | S Series | K Seriesシリーズ | |||

| K-Standard | KD | KDC | |||

| Max. Roll Width | 1700mm | 1200mm | 1700mm | 1600mm | 800mm |

| Max. Roll Diameter | Φ1500mm | Φ1300mm | Φ1500mm | Φ1300mm | Φ800mm |

| Max. Rewind Width | 1695mm | 1200mm | 1700mm | 1600mm | 800mm |

| Max. Rewind Capacity | 1500m/分 | 400m/分 | 1700mm | 1600mm | 800mm |

| Min. Slitting Width | 150mm | 40mm | 150mm | 40mm | 15mm |

| Minimum Paper Core Outer Diameter (Inner Diameter) | Φ100(Φ76.2) mm |

Φ16(Φ10) mm |

Φ100(Φ76.2) mm |

Φ100(Φ76.2) mm |

Φ100(Φ76.2) mm |

| Material Used | Business Form General (Woodfree Paper) |

Woodfree Paper, Thermal Paper, Carbonless Copy Paper, Electrostatic Recording Paper |

Woodfree Paper, Thermal Paper, Carbonless Copy Paper |

Self-adhesive Paper, Film, Magnetic Film, Paper |

Film, Paper |

| Main Drive Motor | AC Vector Motor | ||||

| Machine Dimension | 4500W ×5500L ×3500H |

3700W ×3750L ×2100H |

4800W ×5700L ×2200H |

5500W ×5400L ×2000H |

2000W ×2400L ×1500H |

| Machine Weight (approx.) |

18t | 4.5t | 12t | 12t | 1.5t |

*Specifications are subject to change without notice for improvement and enhancement purposes.。

<Custom Orders Welcome>

1.Please feel free to consult us regarding any type of material.

2.We also design and manufacture products with specifications beyond those listed above.

3.Through made-to-order production, we provide products that meet your specific needs.