PRODUCTS

Bag Processing Machine

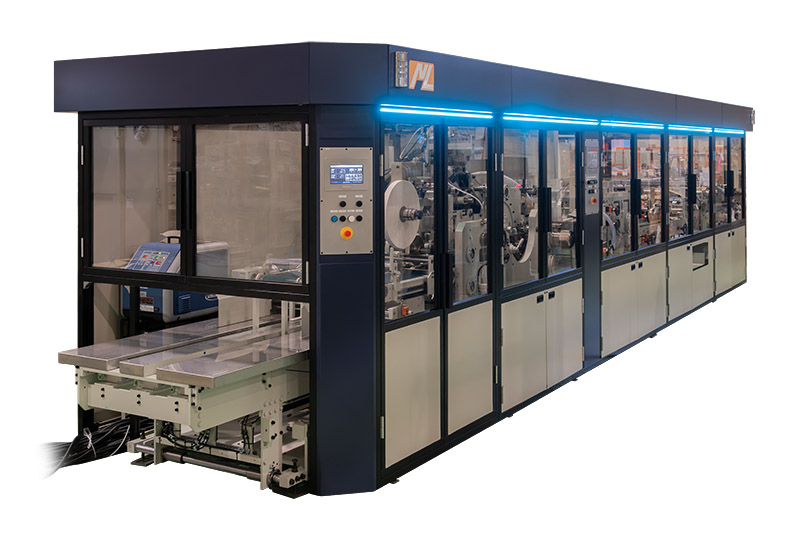

ECB-500

This machine processes square bottom bags and flat bottom bags into e-commerce bags. Bag feeding, alignment positioning, side cuter, creasing, flap cut, hot melt application, release paper pasting, and stacking are performed automatically. The melt gun can be switched between single-row and double-row operation. With full servo drive and intuitive touch panel control, operator training is easy and efficient.

| Bag Width | 200-500mm |

| Bag Length | 320-700mm |

| Finished Bag Length | 320-700mm (including flap) |

| Capacity | Max. 80 bags / minute (In case of 350mm bag width) |

| *Capacity depends on various conditions such as paper quality, basis weight, bag size, etc. |

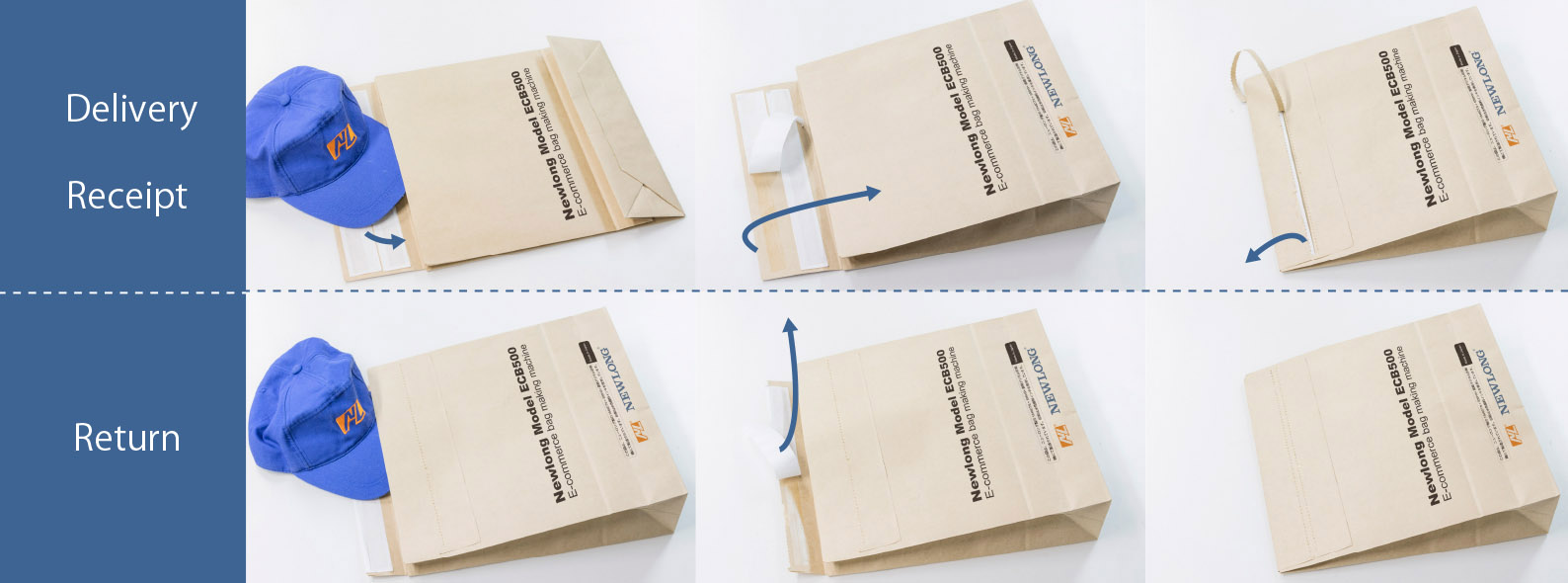

2038FT

Delivery Bag Making Machine

| Bag Width | 200-380mm |

| Bag Length | 340-630mm |

| Finished Bag Length | 300-560mm (including flap) |

| Capacity | Max. 60 bags / minute |

| *Capacity depends on various conditions such as paper quality, basis weight, bag size, etc |

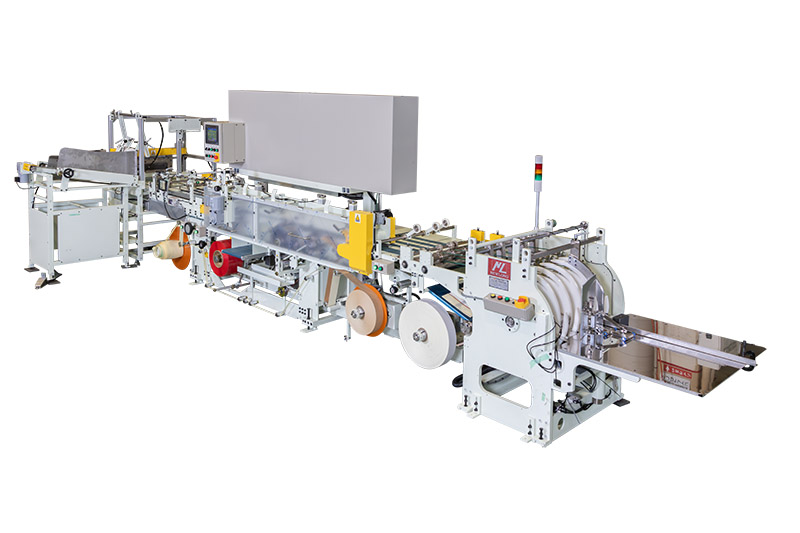

108B

Square Bottom Rice Bag String-Tying Machine

This machine attaches a string to the top of the bag (rice bag), which have been bottom-sealed in advance by a bottomer.

| Bag Length | 202-620mm |

| Bag Width | 80-320mm |

| Bottom Width | 45-115mm |

| String Position | 10-35mm from mouth edge |

| String Length | 350-900mm |

| String Specification | Small Bag: three strand string / Other: five strand string |

| String Pasting | Straight Pasting |

| Glue Used | Vinyl Acetate Adhesive |

| Feeding Capacity | Max. 60 bags / minute (Avoid using bags immediately after being produced. Use only bags that have been pressed and palletized.) |

| Bag Specification | Bleached Kraft Paper, Unbleached Kraft Paper, One-side glazed Paper, Inner Laminated, Outer Laminated, Inner and Outer Laminated |