PRODUCTS

3CM-3/3CM-5

For Poly Bags

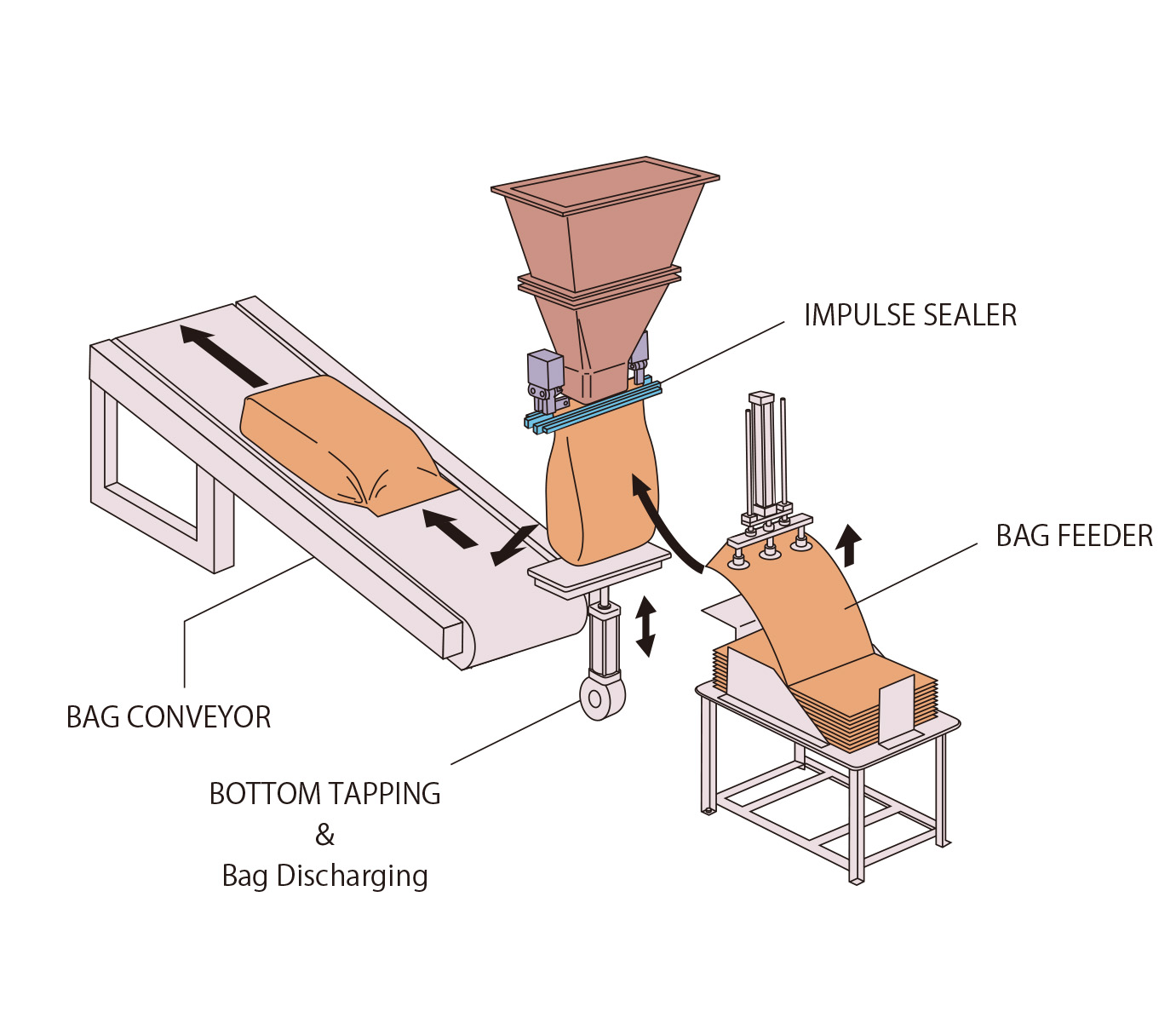

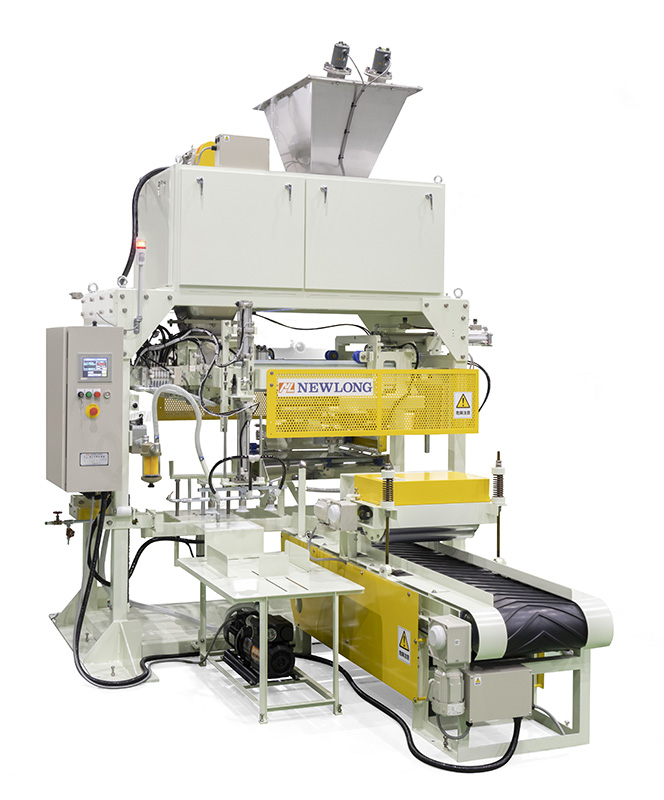

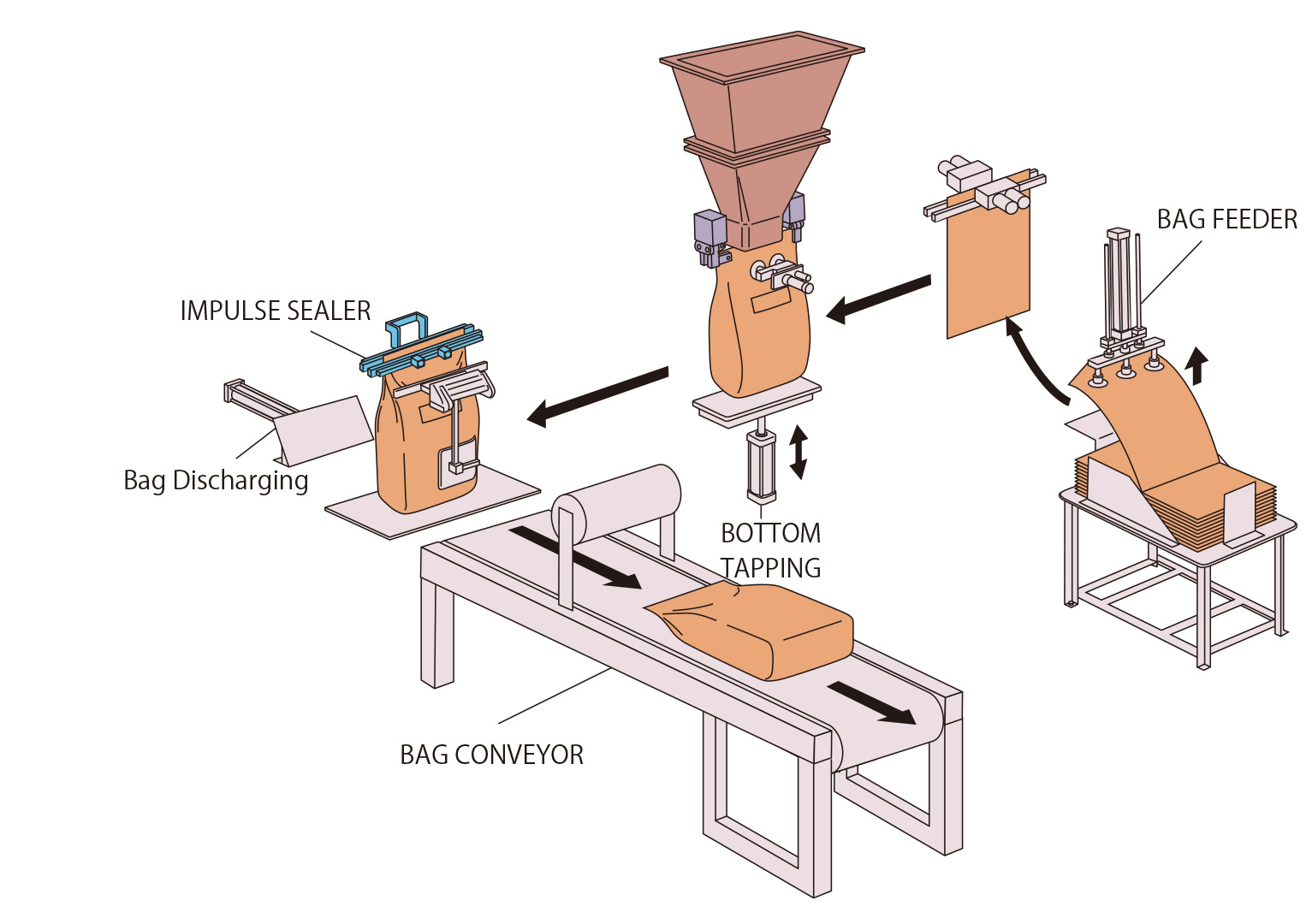

3CM-55

A compact automatic bagging machine integrating a volumetric filler and an impulse sealing unit.

Bag feeding, product filling, sealing, and discharge are all integrated into a single section, achieving a space-saving design. An automatic volumetric filling and bagging machine with rear discharge.

| Capacity (bags/Hour) | 230 *Capacity depends on product character and bag specifications |

| Bag Material | PE bag (with pin-hole) |

| Set Volume | 18~23L |

| Weighing Method | Net / Gross Weighing |

| Bag Sealing Method | Impulse seal |

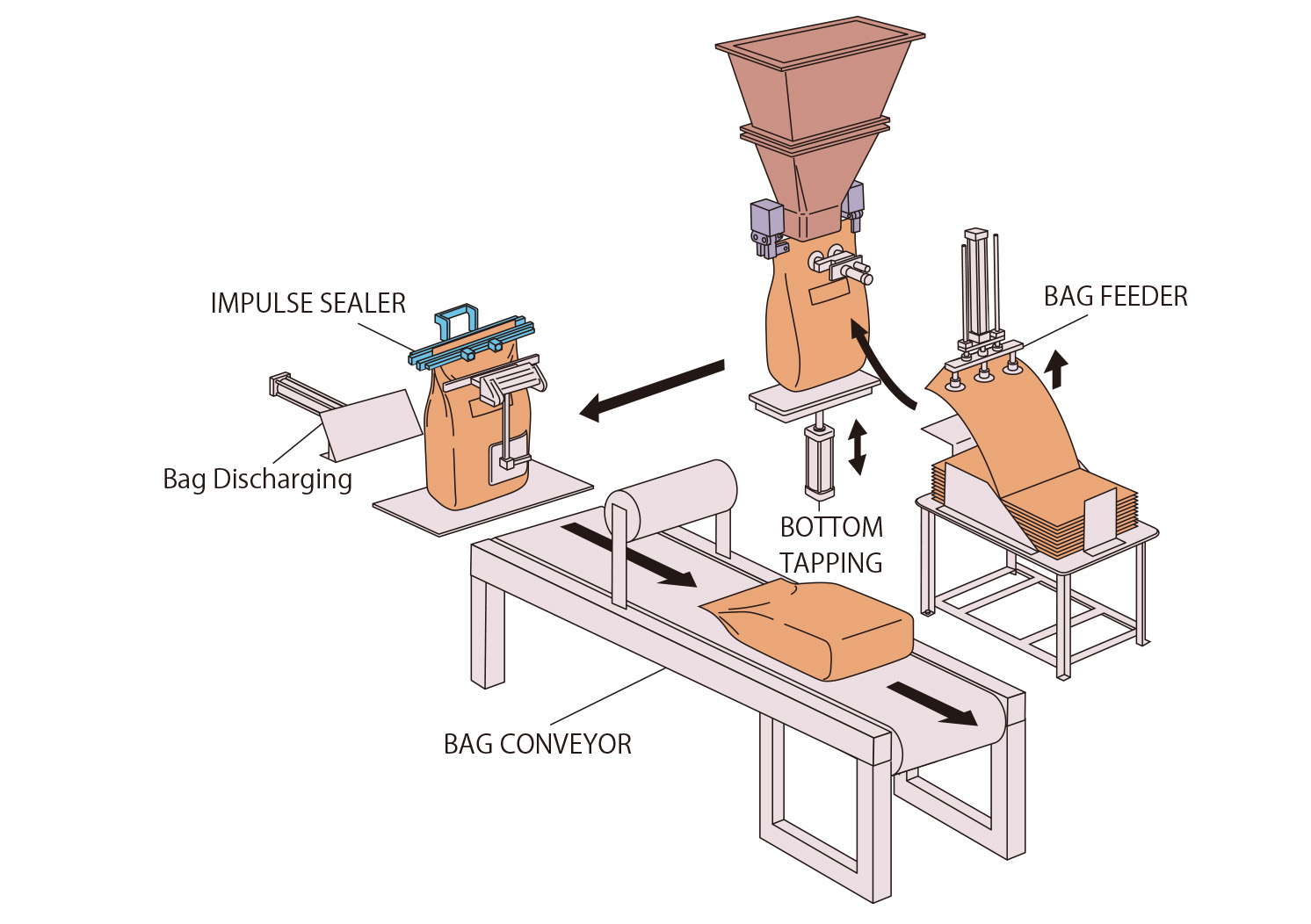

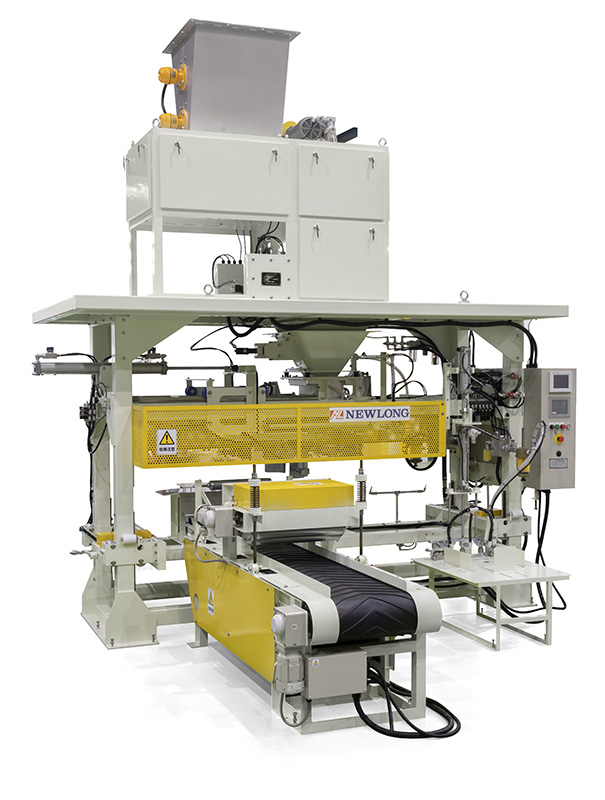

3CM-52

A compact automatic bagging machine integrating a volumetric filler and an impulse sealing unit.

This model is divided into two sections, "bag feed/filling section" and the "impulse seal/discharge section," make this machine is faster than model 3CM-55. The bag feed/discharge directions are selectable.

| Capacity (bags/Hour) | Max. 300 *Capacity depends on product character and bag specifications. |

| Bag Material | PE Bag (with pin-hole) |

| Set Volume | 20~40L |

| Weighing Method | Net/Gross Weighing |

| Bag Sealing Method | Impulse sealing |

3CM-35

A compact automatic bagging machine integrating a volumetric filler and an impulse sealing unit.

This model has improved processing capacity by dividing the machine into three sections: bag supply section, filling section , and impulse seal/discharge section. The bag supply and discharge directions are selectable.

| Capacity (bags/hour) | Max. 350 *Capacity depends on product character and bag specifications |

| Bag Material | PE Bag (with pin-hole) |

| Set Volume | 20~40L |

| Weighing Method | Net/Gross Weighing |

| Bag Sealing Method | Impulse seal |

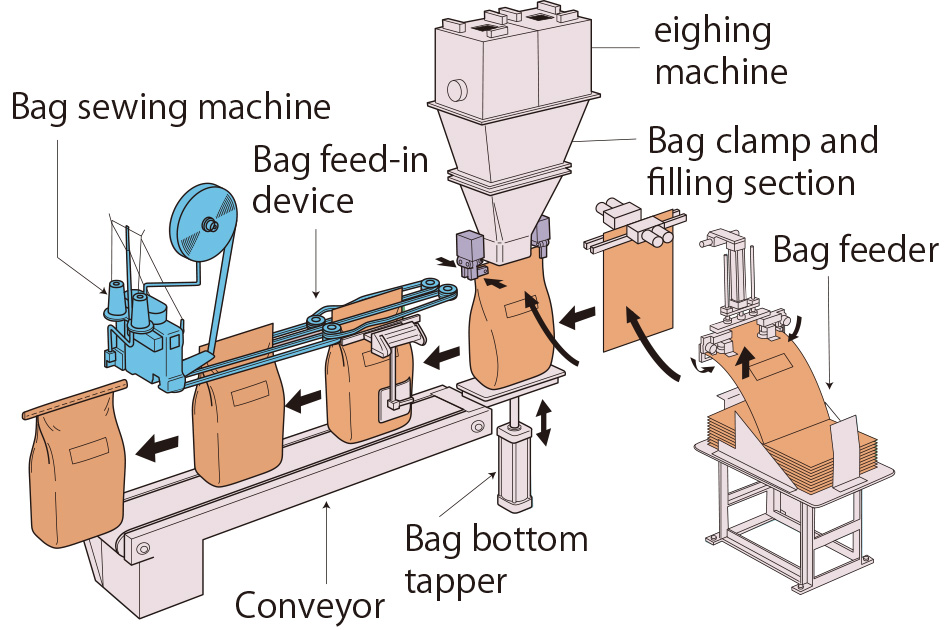

For Paper Bags

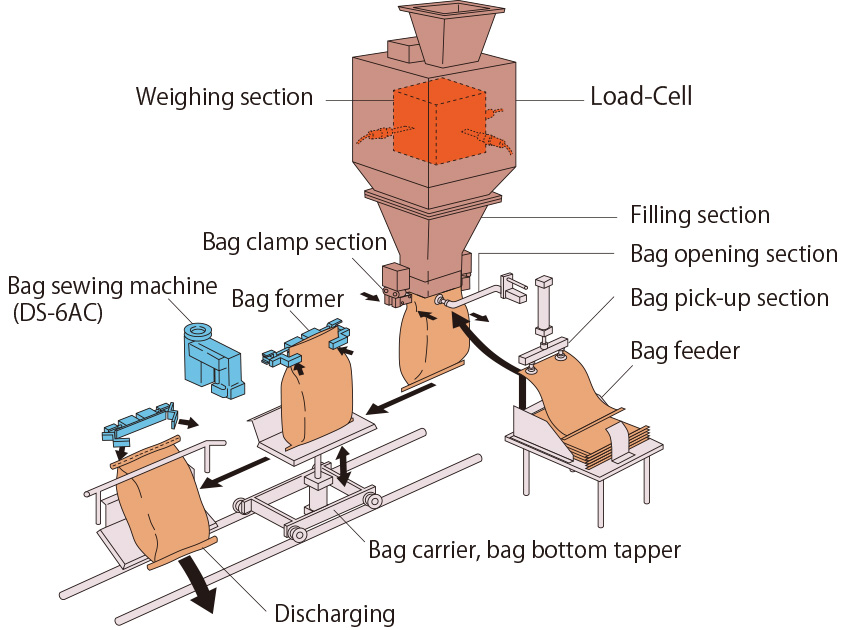

3CM-5B

Successfully made compact, requires less installation space and is low cost. Includes bag tipping device

The cart handles bag transport and bottom tapping. It makes model is less costly and takes up less space than conveyor types.

| Capacity | 120B/H (w/ Sewing head 6m/min) |

| Bag Size | Kraft bag 750~850Lx420Wx76GWmm |

| Filling Weight | 30kg, 25kg |

| Weighing Accuracy | ±1/1000 |

| Power required | Approx. 1.5kW |

| Air consumption | 300NL/min(0.5MPa) |

| 機械重量 | 約800kg |

High Speed Model for both Poly Bags and Paper Bags

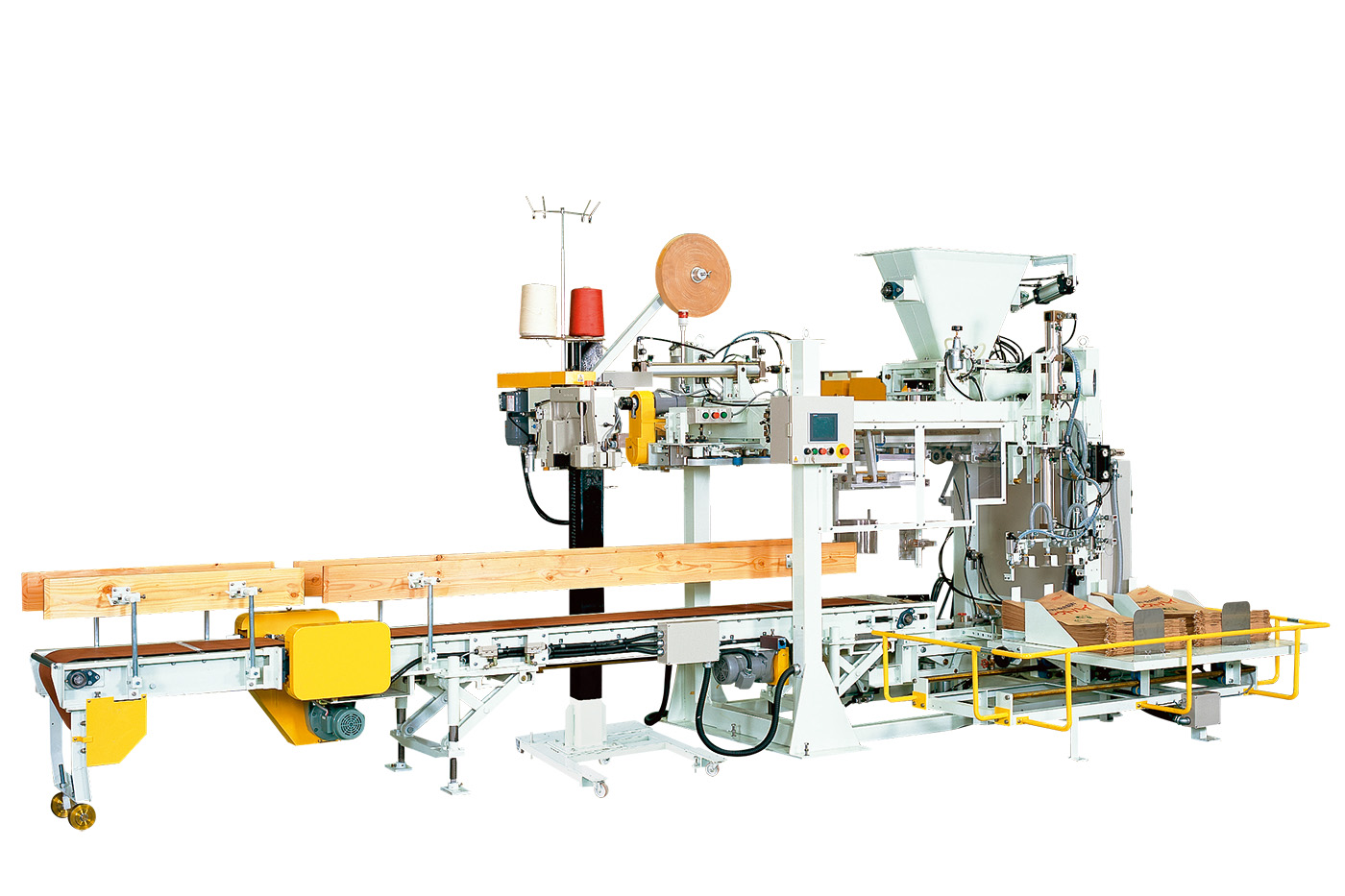

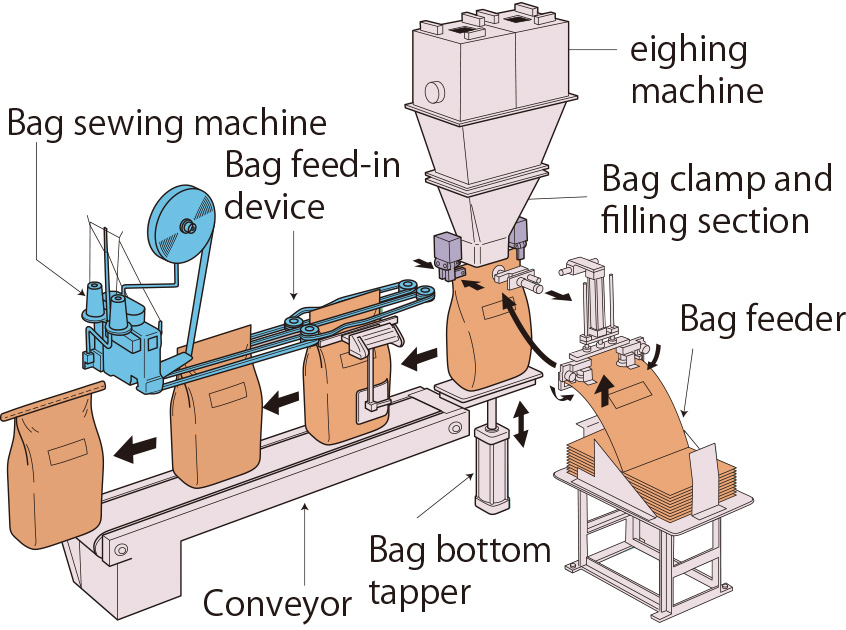

3CM-5U

A model created with the concept of "low cost + high speed"

From bag feeding to bag closing as like ordinal automatic bagging machine with a compact size and high speed.

| Capacity | 450B/H Max:500B/H※1 |

| Bag Material | PE/PP, Paper Kraft |

| Filling Weight | 10~20(kg) |

| Bag Size | 585-640L × 420W × 75GW※2 |

| Weighing Accuracy | ±1/500※1 |

3CM-3U

The concept is the same as the 3CM-5U, wiht the bag feeder is a swing-type and the next bag is set at right before the filling port. Making 3CM-3U to be a hight speed automatic packaging machine.

| Capacity | 600B/H ※1 |

| Bag Material | PE/PP, Paper Kraft |

| Filling Weight | 10~20(kg) |

| Bag Size | 585-640L × 420W × 75GW※2 |

| Weighing Accuracy | ±1/500※1 |

※1(depending on products, bag size and bag materials)

※2(depending on products’ character)